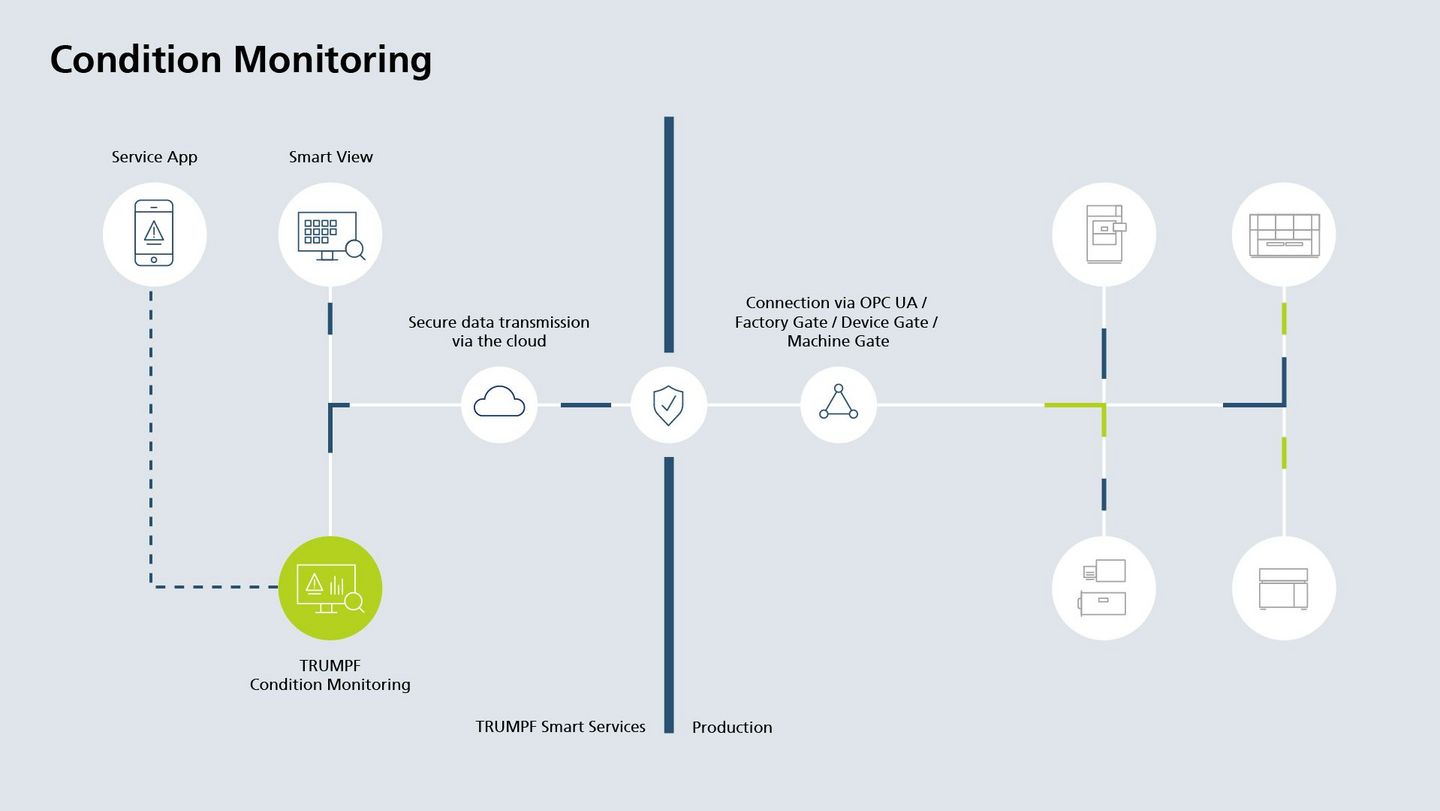

With Condition Monitoring, TRUMPF service experts and algorithms monitor your lasers and systems for the purpose of anticipatory maintenance. The basis is the proactive analysis of your equipment for anomalies – for Condition Monitoring, this happens cyclically; for Condition Check once at an agreed point in time. Condition Monitoring in particular optimally ensures ongoing operation; service experts regularly check the devices, using algorithms and their experience, and identify erroneous states before a failure occurs. If a laser is at risk of failing due to a decreasing cooling water level, for example, or due to a dirty filter, TRUMPF contacts you proactively. Inefficient states, such as the unsuitable control of the laser devices or systems, are quickly identified. You can find the results of the analysis in the cyclical Condition Monitoring Reports. You will have the opportunity to subsequently discuss the recommended measures with a TRUMPF service expert.

![[Translate to en_CN:]](/filestorage/TRUMPF_Master/_processed_/4/2/csm_Smart-View-Keyvisual-169_208984fee6.jpg)