Challenges

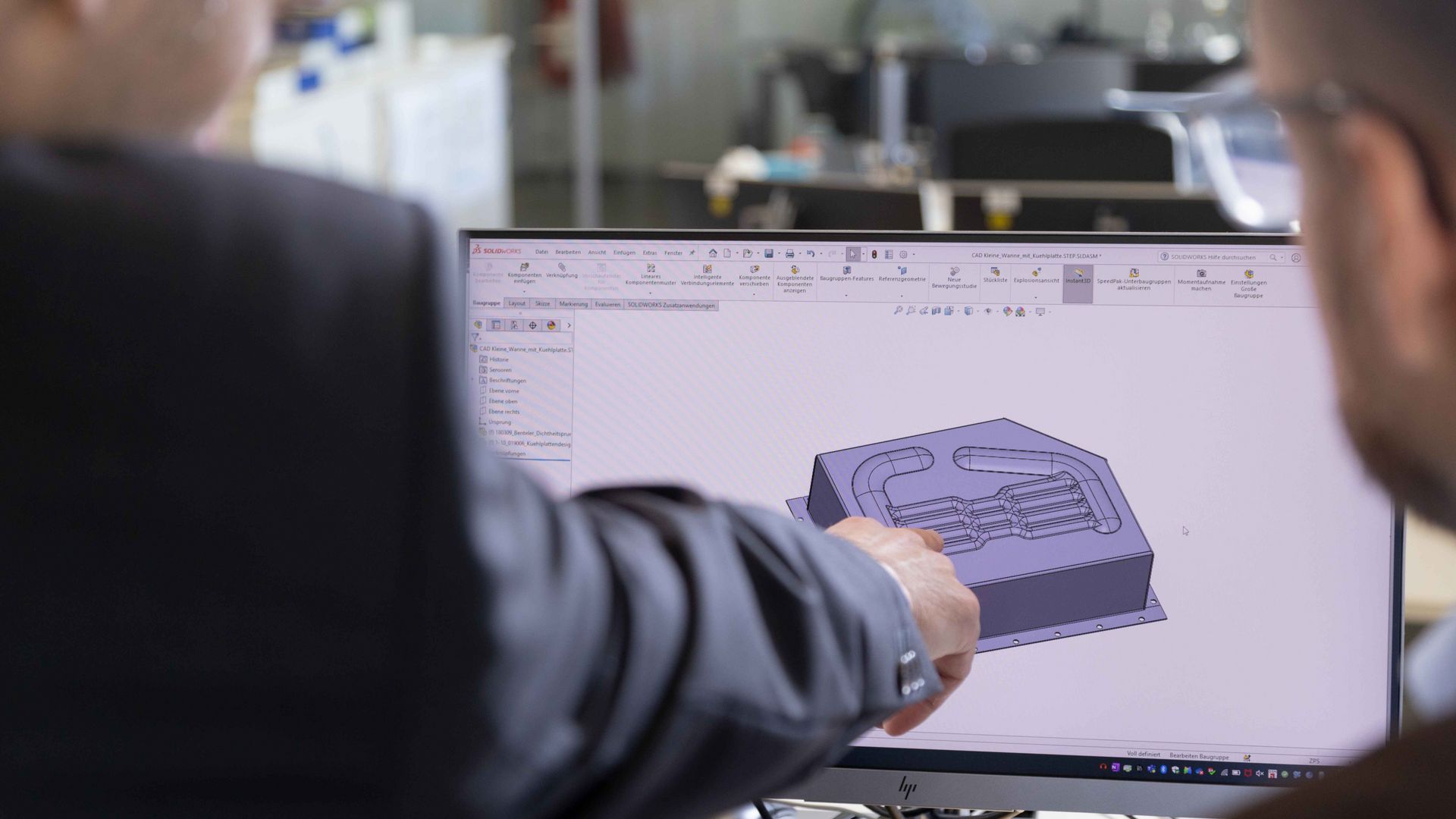

High-voltage battery storage units and the battery boxes that surround them form the heart of electric vehicles. The latter not only protect the sensitive cells from the consequences of crashes, but also from external influences such as humidity and temperature fluctuations, which can have a negative impact on the battery's performance. Until now, these battery boxes have mainly been made of aluminum alloys. They are lightweight and thus aim to maximize the vehicle's range. However, Christian Buse and his colleague Conrad Frischkorn, both development engineers in the Automotive Division at BENTELER, also see great potential in stainless steel as a material. Together they are developing a special design for a flexible and scalable battery box: the folding box concept. A high level of manufacturing process expertise is required, explains Buse: "We sought support from TRUMPF for the design of the overall manufacturing process. For the experts from the battery pack industry management team, the major challenge was to develop a fast and reproducible laser welding process for gas-tight welding of stainless steel.