TruFiber P compact

Whether as an air-cooled precision tool with up to 500 W or as the water-cooled variant with up to 2 kW laser power – our TruFiber P compact lasers are the ideal solution for a variety of applications. This includes, for example, additive manufacturing, laser precision welding in the automotive industry or laser precision cutting in medical technology.

The TruFiber P compact series lasers belong to the compact class of the CW lasers at TRUMPF and are available in a handy 19 inch format with laser power of up to 2 kW.

TruFiber P compact lasers do not need any maintenance intervals and very rarely require unscheduled service assignments due to their excellent product quality and long service life.

TruFiber P compact lasers have a patented technology which not only protects the laser from the damaging effects of back reflected light but also makes it possible to process materials such as copper, brass or gold productively and with no hassle.

The integrated safety concept offers the highest safety level (PLe) for automatic shutdown if there is an interruption in the safety circuit.

Laser cutting stents

Due to the delicate properties, cutting medical stents not only requires a high degree of precision when positioning a small cutting point (~20 µm), but also a very high level of quality of the cutting area, as the finished part must have no rough edges or deposits which could detach after implantation. The excellent beam quality of the single-mode TruFiber P compact fibre lasers is predestined for this application.

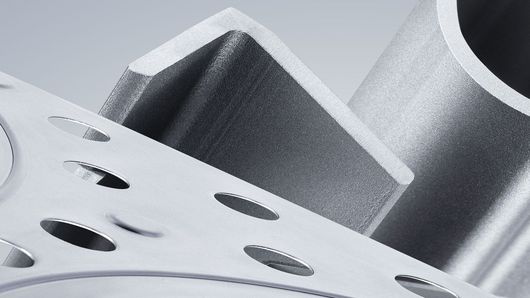

Laser cutting reflective materials such as brass, for example

Thin brass sheets of 1 mm can be cut perfectly with single-mode TruFiber P compact fiber lasers with a small focal diameter (approx. 30 µm). The lasers facilitate a high level of material removal – with a narrow kerf (cutting width) at the same time. The 2 kW lasers which achieve high cutting speeds with their multi-mode beam and a focal diameter of 50 µm are suitable for thicker materials (up to 6 mm thick), and cut sharp, high quality edges.

3D printing dental products such as crowns, for example

Metallic 3D printing can be carried out in dental surgeries as well as in specialized dental laboratories. Customized dental products such as crowns or implants, for example, can be economically 3D printed to a high standard using materials such as cobalt chrome. The TruFiber P compact fiber lasers are used to melt the metallic powder and to build up the components in the powder bed layer-by-layer.

|

TruFiber 100 P compact (FD44-A)

Compare product

|

TruFiber 200 P compact (FD44-A)

Compare product

|

TruFiber 300 P compact (FD44-A)

Compare product

|

TruFiber 300 P compact (FD44-W)

Compare product

|

TruFiber 301 P compact (FD44-A)

Compare product

|

TruFiber 301 P compact (FD44-W)

Compare product

|

TruFiber 303 P compact (FD44-W)

Compare product

|

TruFiber 500 P compact (FD44-A)

Compare product

|

TruFiber 500 P compact (FD44-W)

Compare product

|

TruFiber 501 P compact (FD44-W)

Compare product

|

TruFiber 503 P compact (FD44-W)

Compare product

|

TruFiber 1000 P compact (FD44-W)

Compare product

|

TruFiber 1001 P compact (FD44-W

Compare product

|

TruFiber 1003 P compact (FD44-W)

Compare product

|

TruFiber 1500 P compact (FD44-W)

Compare product

|

TruFiber 1501 P compact (FD44-W)

Compare product

|

TruFiber 1503 P compact (FD44-W)

Compare product

|

TruFiber 2000 P compact (FD44-W)

Compare product

|

TruFiber 2001 P compact (FD44-W)

Compare product

|

TruFiber 2003 P compact (FD44-W)

Compare product

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||||||||||

| Laser power at the LLK plug | 100 W | 200 W | 300 W | 300 W | 300 W | 300 W | 300 W | 500 W | 500 W | 500 W | 500 W | 1000 W | 1000 W | 1000 W | 1500 W | 1500 W | 1500 W | 2000 W | 2000 W | 2000 W |

| Typical power constancy at rated power | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) |

| Continuously adjustable power range | 10 W - 100 W | 20 W - 200 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

| Beam quality | 0.38 ± 0,03 mm▪mrad | 0.38 ± 0,03 mm▪mrad | 0.38 ± 0,03 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 25 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

| Wavelength spectrum | 1068 nm - 1072 nm | 1068 nm - 1072 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm |

| Diameter of laser light cable | 10 μm | 10 μm | 20 μm |

20 μm

50 μm |

100 μm | 100 μm | 300 μm |

20 μm

50 μm |

20 μm

50 μm |

100 μm | 300 μm |

20 μm

50 μm |

100 μm | 300 μm |

20 μm

50 μm |

100 μm | 300 μm |

25 μm

50 μm |

100 μm | 300 μm |

| Length of the laser light cable | 5 m | 5 m | 10 m | 10 m | 10 m | 10 m | 10 m | 10 m |

15 m (for 20 μm LLK Ø)

15 m (for collimated output) 20 m (for 50 μm LLK Ø) |

20 m | 20 m |

15 m

20 m |

20 m | 20 m |

15 m (for 20 μm LLK Ø)

20 m (for 50 μm LLK Ø) |

20 m | 20 m |

10 m (for 25 μm LLK Ø)

20 m (for 50 μm LLK Ø) |

20 m | 20 m |

| Structural design | ||||||||||||||||||||

| Dimensions (W x H x D) | 445 mm x 177 mm x 502 mm | 445 mm x 177 mm x 502 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 266 mm x 833 mm | 445 mm x 266 mm x 833 mm | 445 mm x 266 mm x 833 mm |

| Maximum number of laser light cables | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Installation | ||||||||||||||||||||

| Ambient temperature | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C |

| Cooling | Air | Air | Air | Water | Air | Water | Water | Air | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water |

|

TruFiber 100 P compact (FD44-A)

|

TruFiber 200 P compact (FD44-A)

|

TruFiber 300 P compact (FD44-A)

|

TruFiber 300 P compact (FD44-W)

|

TruFiber 301 P compact (FD44-A)

|

TruFiber 301 P compact (FD44-W)

|

TruFiber 303 P compact (FD44-W)

|

TruFiber 500 P compact (FD44-A)

|

TruFiber 500 P compact (FD44-W)

|

TruFiber 501 P compact (FD44-W)

|

TruFiber 503 P compact (FD44-W)

|

TruFiber 1000 P compact (FD44-W)

|

TruFiber 1001 P compact (FD44-W

|

TruFiber 1003 P compact (FD44-W)

|

TruFiber 1500 P compact (FD44-W)

|

TruFiber 1501 P compact (FD44-W)

|

TruFiber 1503 P compact (FD44-W)

|

TruFiber 2000 P compact (FD44-W)

|

TruFiber 2001 P compact (FD44-W)

|

TruFiber 2003 P compact (FD44-W)

|

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Laser parameters | ||||||||||||||||||||

| Laser power at the LLK plug | 100 W | 200 W | 300 W | 300 W | 300 W | 300 W | 300 W | 500 W | 500 W | 500 W | 500 W | 1000 W | 1000 W | 1000 W | 1500 W | 1500 W | 1500 W | 2000 W | 2000 W | 2000 W |

| Typical power constancy at rated power | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) | ± 2 % (peak) |

| Continuously adjustable power range | 10 W - 100 W | 20 W - 200 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W | 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

50 W - 500 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

100 W - 1000 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

150 W - 1500 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

200 W - 2000 W

Low power mode 30 W - 300 W |

| Beam quality | 0.38 ± 0,03 mm▪mrad | 0.38 ± 0,03 mm▪mrad | 0.38 ± 0,03 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

0.38 ± 0,03 mm▪mrad (for collimated output) 2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 20 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

0.38 ± 0,03 mm▪mrad (for 25 μm LLK Ø)

2.1 ± 0.3 mm▪mrad (for 50 μm LLK Ø) |

3.3 ± 0.6 mm▪mrad | 13 ± 4 mm▪mrad |

| Wavelength spectrum | 1068 nm - 1072 nm | 1068 nm - 1072 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1078 nm - 1082 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm | 1073 nm - 1077 nm |

| Diameter of laser light cable | 10 μm | 10 μm | 20 μm |

20 μm

50 μm |

100 μm | 100 μm | 300 μm |

20 μm

50 μm |

20 μm

50 μm |

100 μm | 300 μm |

20 μm

50 μm |

100 μm | 300 μm |

20 μm

50 μm |

100 μm | 300 μm |

25 μm

50 μm |

100 μm | 300 μm |

| Length of the laser light cable | 5 m | 5 m | 10 m | 10 m | 10 m | 10 m | 10 m | 10 m |

15 m (for 20 μm LLK Ø)

15 m (for collimated output) 20 m (for 50 μm LLK Ø) |

20 m | 20 m |

15 m

20 m |

20 m | 20 m |

15 m (for 20 μm LLK Ø)

20 m (for 50 μm LLK Ø) |

20 m | 20 m |

10 m (for 25 μm LLK Ø)

20 m (for 50 μm LLK Ø) |

20 m | 20 m |

| Structural design | ||||||||||||||||||||

| Dimensions (W x H x D) | 445 mm x 177 mm x 502 mm | 445 mm x 177 mm x 502 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 221.5 mm x 622.1 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 133.4 mm x 681 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 177 mm x 833 mm | 445 mm x 266 mm x 833 mm | 445 mm x 266 mm x 833 mm | 445 mm x 266 mm x 833 mm |

| Maximum number of laser light cables | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Installation | ||||||||||||||||||||

| Ambient temperature | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 40 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C | 5 °C - 45 °C |

| Cooling | Air | Air | Air | Water | Air | Water | Water | Air | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water | Water |

The technical data of all product versions as a download.

Focusing optics

Regardless of whether you are welding, cutting, ablating, heating, or drilling, you can count on high-quality process results with robust focusing optics from TRUMPF.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.