Denis Lozusic loves to run marathons. He doesn't train for them doggedly every day. He just has a solid basic fitness level and the right mindset. "Whenever I set myself a target – whether in sports or business – I put my whole heart into it to reach that goal," he explains. "And I know I can achieve it, no matter what happens. I follow through till it's accomplished." Sounds simple. But that requires a great deal of self-confidence and staying power. Denis Lozusic is so successful because he persists and follows through even when something doesn't go to plan.

Starting out with obstacles

Denis Lozusic knew that he wanted to set up his own business even when he was CEO at a large metal processing company. When he had the opportunity to purchase a company in Neustetten in Baden-Wuerttemberg in 2018, he jumped at the chance and turned it into DELO Maschinenbau GmbH & Co. KG. It wasn't easy: along with just one employee, he rolled up his sleeves and brought order into the chaos. "We had customers who were interested, who wanted to place orders with us, but we just didn't have the space to produce anything - let alone build large special machines," he says. But just like in sports, Lozusic tuned out all the problems and gave his full attention to his goal. In his mind's eye, he could envision an ultra-modern production with machines by TRUMPF. He knew and appreciated them from his old company. And he achieved it - today DELO is a highly specialized provider for customized special machine and systems engineering, currently staffed with 17 employees.

A partner provides a leg-up

Mid 2021, Lozucis invested in the first TRUMPF machine, a TruBend 7050. Then he got an offer he called a fortunate stroke of fate: his TRUMPF sales representative recommended DELO as a test customer for a 2D laser cutting machine – the new TruLaser 1030 fiber. "That was a real vote of confidence for a relatively small and young company like ours. And it came at just the right time for us, because our old laser cutting machine had reached its limit and was anything but reliable in terms of processes," explains Lozusic.

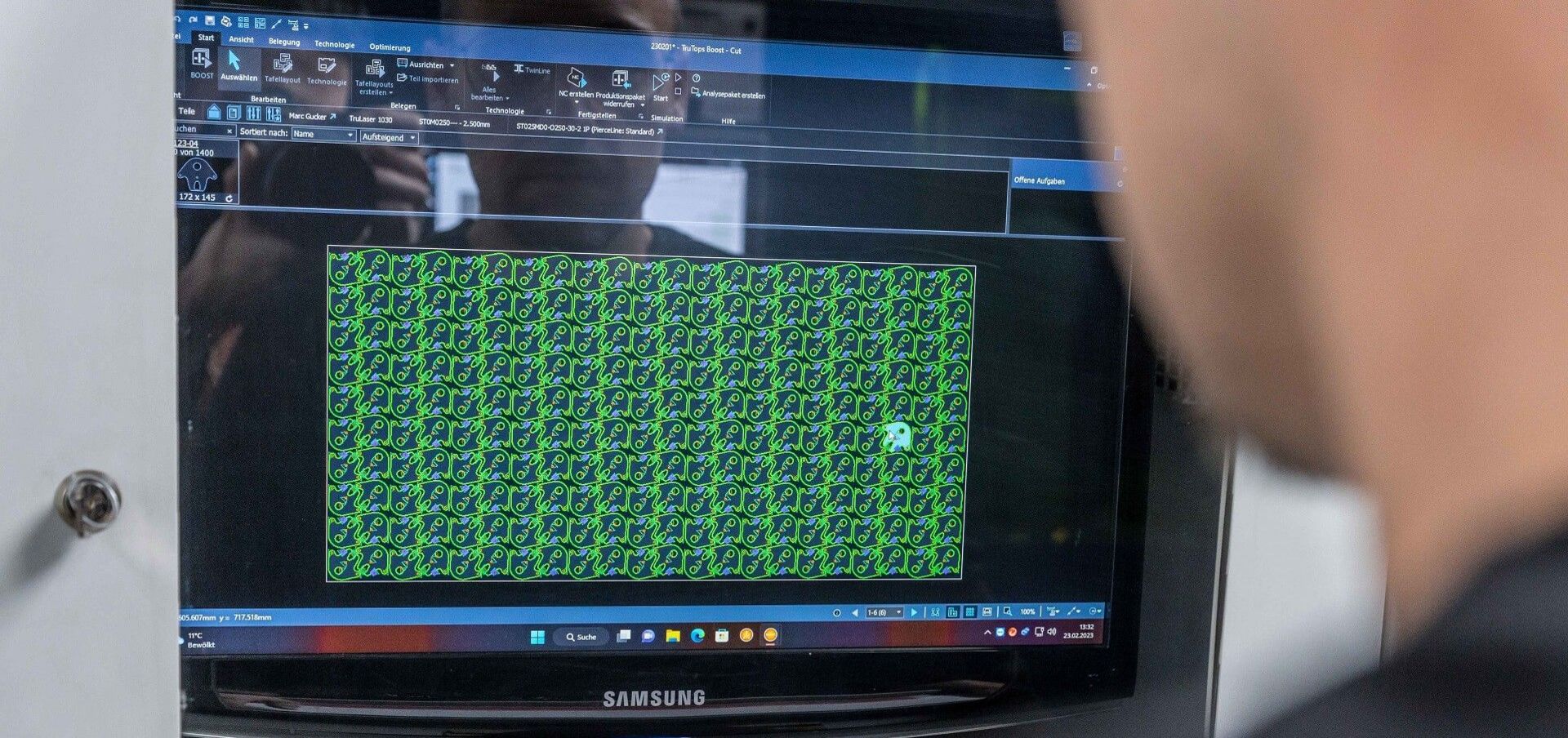

70 percent less cutting gas

Even in the test phase, the TruLaser 1030 fiber at DELO showed what it could do. "The machine has a high cutting speed with superb processing quality," explains Lozusic. And even the non-productive times have decreased drastically compared to before. "The machine's automatic nozzle changer saves time while also increasing process reliability in unattended production," he says and continues. "Thanks to the CoolLine function, we can keep the temperature in the cutting process almost constant which means we can accommodate more parts on a sheet – even parts with very delicate contours. That saves material costs and helps us to be even more productive." The low cutting gas consumption of the TruLaser 1030 fiber reduces costs significantly as well. "When cutting stainless steel in the thickness range of three to 20 millimeters, we consume up to 70 percent less nitrogen with the HighSpeed Eco function," explains Lozusic. All these factors have a direct impact on pricing: "We can keep up with the competition in terms of price and have already gained a new customer."

Energy costs reduced by two thirds

Just like everywhere else, rising energy costs are a serious subject at DELO. This is why Denis Lozusic is particularly pleased with the efficiency of the TruLaser 1030 fiber: "We have been able to reduce our energy costs by two thirds compared to our previous machine," he explains. Furthermore, this enormous savings secured the company a grant of 40,000 euros from BAFA (Federal Office for Economic Affairs and Export Control). "TRUMPF provided support with efficiency calculations and created comparison tables based on recurring parts with values from TruLaser 1030 fiber and the old system. This was an immense help when applying for the grant," says Lozusic.

Set up, switch on, go

Denis Lozusic was impressed with how easy it is to operate the TruLaser 1030 fiber: "The TRUMPF service team set up the machine, put it into operation and we could start immediately." The intuitive touch panel and the vast amount of cutting data already stored makes it easy to get started. "I sent two employees to TRUMPF for training, and colleagues are instructing two apprentices here in-house," he explains. "This meant we could work productively with the machine from the very beginning."

Eyes on the prize

In the medium term, Lozusic is hoping for a healthy ten percent increase in turnover. A goal he believes is definitely feasible thanks to a loyal customer base, competent partners such as TRUMPF and his motivated staff. Machines like the TruLaser 1030 fiber play their part. The enterprising businessman has already created room for growth - Denis Lozusic has more than doubled his production space with a new production hall in neighboring Hechingen. There, the laser machine will be able to show what it can do in two-shift operation. "To call the TruLaser 1030 fiber an entry-level machine is an understatement in my opinion," summarizes Lozusic. "There are no doubt faster systems for contract manufacturers, but for mechanical engineers and mid-sized companies, the machine has everything it needs to work efficiently. It delivers the speed right away but it doesn't lose capacity in the long term. That is exactly what we need. Our success is not just a quick sprint. We are in it for the long haul, more like a marathon."