Nowadays, a dull weightlifting session at the gym is not enough to get people off the couch. Modern gyms therefore invest in fancy equipment designed to give customers visible results quickly. But it doesn't always pan out for the customers: Many highly motivated beginners at the gym stumble over questions like how much weight and how many repetitions are necessary, or which of the many machines will even bring them closer to their training goal. Frustration and dwindling motivation tend to be the result. If everyone had their own personal trainer, that would be perfect – thought two students in Munich, who then programmed a software that enables personalized training. The user simply holds up their personal user card to a scanner on the EGYM exercise machine. Their personal fitness data and goals are stored on it, as well as a training program specially adapted to their needs. With this data, every piece of equipment becomes your personal trainer. As an added special feature, the software not only specifies the type and duration of the individual exercises, but also visualizes the movement sequence and thus ensures that the user performs the exercises correctly.

The perfect frame from a single source

In 2011, the EGYM founders sought support from Steinhart Metallwarenfabrik in Hettingen, Swabia, for the design and manufacture of the first exercise machine. Production manager Patrick Genkinger recalls: "They came with the software and wanted a suitable exercise machine that was to be completely manufactured from one source. We then worked together to develop a prototype that was precisely tailored to our manufacturing spectrum."

And that is clearly seen: From the punch laser machine to a bending cell and three laser tube-cutting machines, Steinhart offers the entire range of sheet metal processing. "We rely exclusively on TRUMPF machines here," Genkinger explains, and adds, "When designing the frame for the first EGYM, our in-depth expertise of laser tube cutting was particularly helpful." 70% of the frame of the unit consists of visually attractive oval tubes made of sturdy mild steel. "We use both our TruLaser Tube 5000 and our TruLaser Tube 7000 for processing. Both are equipped with the bevel cutting option and can insert threads." What would normally take several work steps to implement in conventional manufacturing, TRUMPF's laser tube-cutting machines accomplish in just one operation. The aluminum checker plate for placing the legs comes scratch-free from the TruMatic 7000, and the TruBend 7036 Cell takes care of the necessary bending edge for fastening to the frame. The electronics and some plastic parts are supplied to Steinhart. After the frames are powder coated, all components are assembled into complete units.

MyTRUMPF for fit machines

Steinhart now manufactures numerous EGYM units per month and the smart machines can be found in premium gyms throughout Europe. "Our production is based on customer order, meaning we have fixed delivery dates," explains Genkinger. "So it's important that all production machines are in good shape at all times. We can't afford any downtimes or failures." The MyTRUMPF digital online customer portal and the TRUMPF Service app provide him with valuable support.

My products, my portal

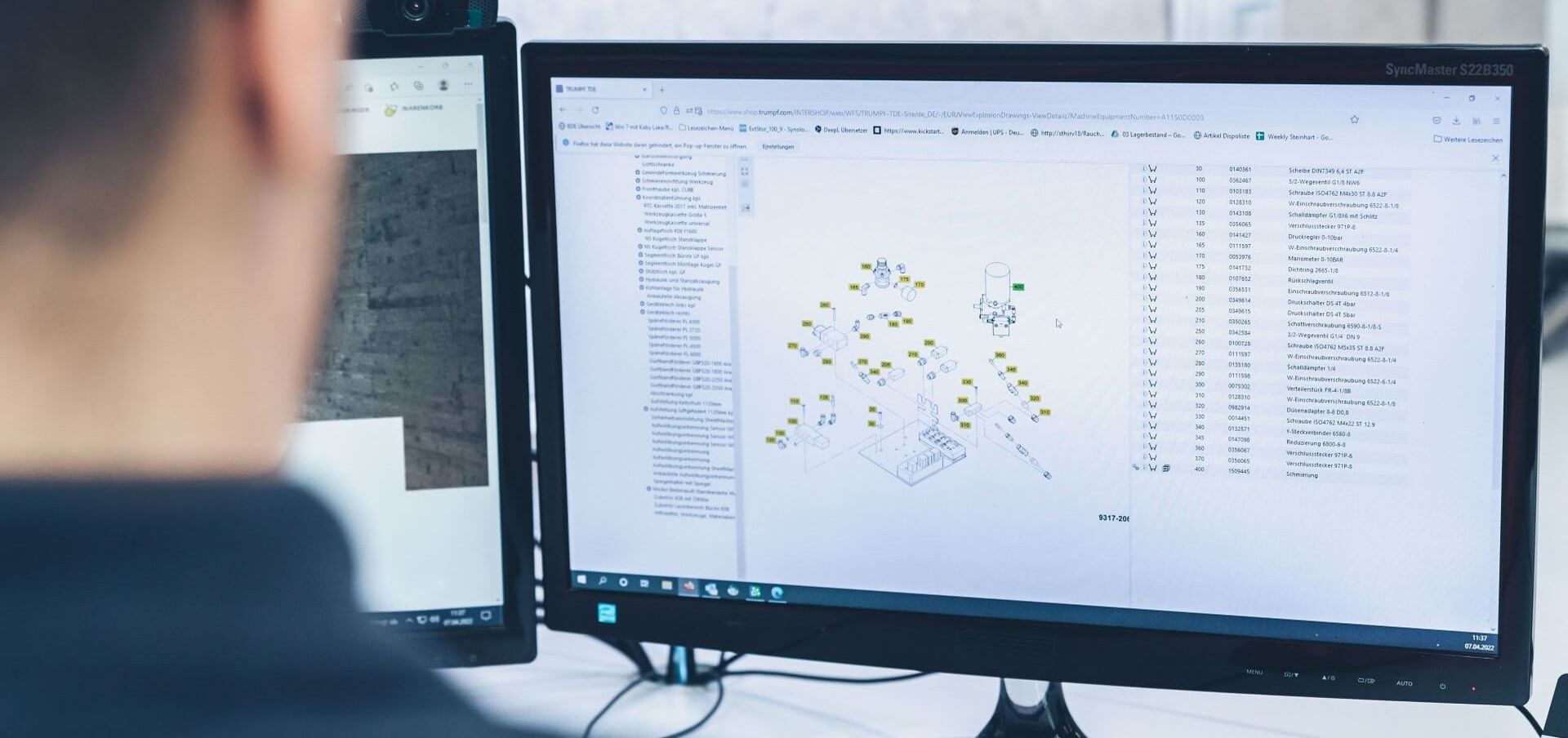

All Steinhart machinery is recorded with all important equipment and software information in its personal MyTRUMPF portal. An E-Shop for spare parts and consumables as well as for bending and punching tools makes ordering possible around the clock. Among other things, it is possible to view orders and download invoices, as well as to call up and track all reported service cases. "After logging in, I select the machine for which I need parts and then have several options to select and order the spare part or consumable that I'm looking for. It only takes a few minutes and saves me a lot of time," explains Genkinger. His favorite is the parts selection via the "exploded view" function, where all machine parts are displayed in one application. One click on what you are looking for and the order is initiated. Alternatively, Genkinger can enter the order numbers directly using the Quick Order function. "And if I recently ordered a part, I look for the order number in the MyTRUMPF order history. I can find what I'm looking for very quickly there." Genkinger is also impressed by the search function in the E-Shop for punching and bending tools: "It works like a charm. I buy my tools almost exclusively in the E-Shop."

Fast results with digital support

Patrick Genkinger is also enthusiastic about TRUMPF's Service app because it saves him valuable time. "When I have a problem, I create a service case in the app. To do this, I select the affected machine from a pre-configured list of my systems. This saves me the trouble of first searching for a machine number. A service employee will get back to me in next to no time," explains Genkinger and continues. "I think it's great that I can upload photos, so the service engineer can get a better idea of my problem right away and provide assistance in a targeted manner." Once the service case has been created, Genkinger can view the processing status at any time via the app or MyTRUMPF. The Technical Guides, i.e. tutorials, which the Service app displays after entering several error numbers, are also a great aid for self-help. "By using these, we were able to fix almost all of the few service cases that we had in the last two years ourselves," he says delightedly.

Taking a targeted approach

The MyTRUMPF online platform and Service app show that personalized solutions can offer real added value. And Patrick Genkinger doesn't want to do without that anymore. "In my production, it saves me a lot of time," he says with a grin, swinging himself onto an EGYM rowing machine and pulling the bar with the weights to his chest. "And when it comes to fitness, having a workout program tailored specifically to me is way more fun."