It may sound like wishful thinking, but controlling a production site with a cell phone has long been a reality. A number of companies have taken this lesson on board during the coronavirus pandemic – including Spanish job shop Ripleg S.A.U. “We only had around 15 of our 75 employees working on the shop floor during the height of the pandemic. This crisis has shown us that we can do a great job of controlling and monitoring our production site working from home. We used our smartphones for all the various processes, from accepting and forwarding orders to creating production jobs and programming the machines,” says Managing Director Jordi Batlle.

STOPA system gets things organized

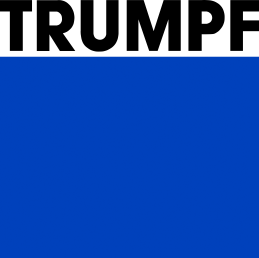

The idea of automated, digital manufacturing has long been firmly established at Ripleg, a family-run company based in the Spanish town of Ripoll. Company founder Eudald Batlle Santanach and his children transformed the business step-by-step. They began their automation journey with Eudald Batlle’s purchase of a TRUMPF punching machine with SheetMaster in 2003. This punching machine was followed by an automated laser cutting machine one year later. In 2006, Batlle acquired a second punching machine and connected both the punching machines to two STOPA storage towers with a total of 60 storage compartments. Jordi Batlle recalls what a difference it made: “Covering the initial investment costs wasn’t easy, but the automated supply of materials from the STOPA towers greatly accelerated our production operations.” More additions were to come with the purchase of two automated bending machines in 2008 and 2011 and the high-end TruMatic 7000 punching and laser cutting machine in 2016. “After that, I suggested to my father that he should perhaps stop visiting Ditzingen for a while. I told him we had enough machines!” says Jordi Batlle with a smile.

Streamlining through software

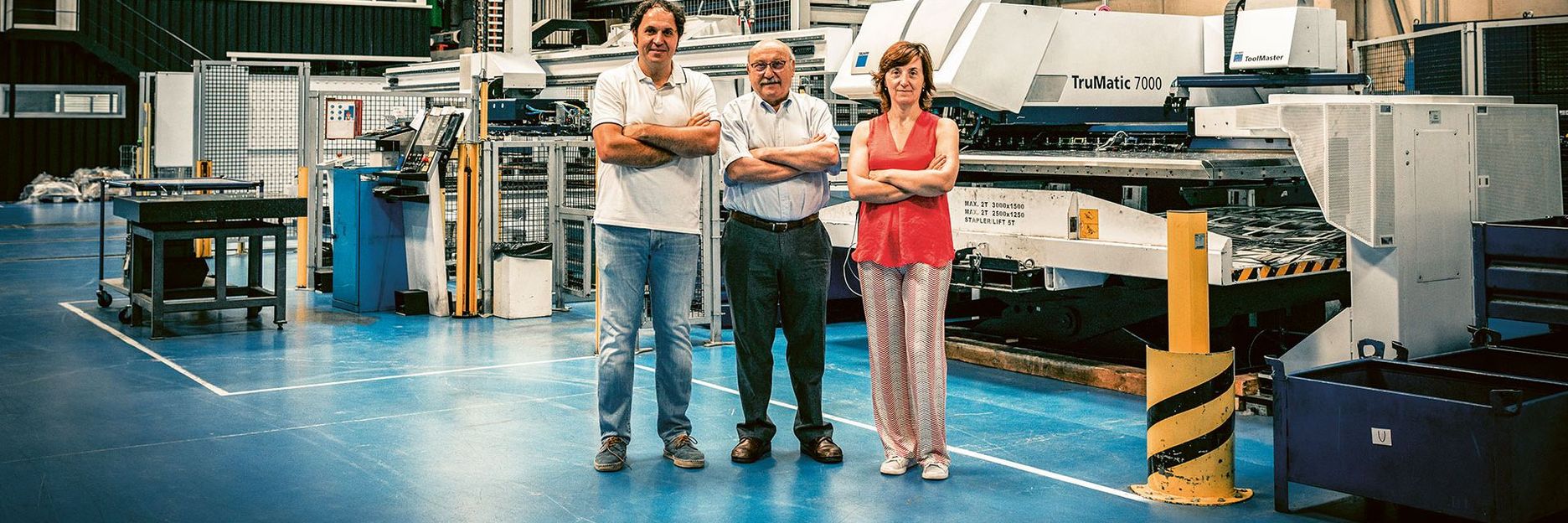

Even the most efficient machines and the fastest automation components are of little use if a company fails to give its processes enough structure. Ripleg knew that it had to optimize and digitize its production processes step-by-step as well as buying modern machinery. “When we got the TruMatic 7000, we completely reconfigured our shop floor to streamline the production pro-cesses,” says Jordi Batlle . Storage capacity increased by another 30 compartments to reach a total of 90, and the TruMatic 7000 was also hooked up to the STOPA system. “We started working with the TruTops Fab production control system in 2008,” says Jordi Batlle. “By carefully programming the software, we managed to cut the number of materials we need to have in stock from 180 to today’s figure of 70. We’ve also seen big reductions in material wastage. By fabricating multiple jobs at the same time, we can fit more parts on the same sheet.”

Producing by numbers

Jordi Batlle was convinced there was even more potential to improve transparency and throughput times. So, in the summer of 2017, he decided to harness TRUMPF’s expertise by booking a smart factory consulting session. “It’s always good to get an outsider to take an objective look at how your production facility is running. We thought the consultation would be a good way to identify further optimization potential,” he says.

After conducting a detailed analysis of the company’s processes, the TRUMPF smart factory consultants proposed a range of lean management measures and suggested switching to just-in-time manufacturing. “In the past, we often had parts sitting around on pallets in the production hall for several days waiting for the next step in their processing journey,” says Batlle. “Now things are different. For example, we only punch parts if we know we can send them straight to the bending machine immediately afterwards. That reduces the time we end up storing, transporting and searching for things.

A further boost in efficiency came from collecting and analyzing machine KPIs with the help of the TruTops Monitor condition monitoring software. The software records machine data such as downtimes, error messages, error causes, breaks and maintenance times and produces a transparent overview of how much each machine has been used. It also makes it easier to determine why delays in production occur and rectify the causes. Jordi Batlle is delighted with the results: “This new style of manufacturing and the ability to analyze our KPIs has reduced our throughput times by 55 percent and significantly improved our ability to deliver on time.”

Punching gives a competitive edge

This has obviously gone down well with Ripleg’s customers. The Spanish company has positioned itself as an expert in punching in order to distinguish itself from its mostly laser-dominated competitors. “We love punching,” says Jordi Batlle . “Punching is a fast and cost-effective technology if you have efficient machines, the right tools and a creative approach to part design.” The father and his sons have put all these conditions in place over the years thanks to their passion for the business and the courage to invest in new machinery. Ripleg’s 7,000-square-meter production facility caters to customers from sectors such as heating, ventilation and air-conditioning, food, medicine and packaging. It offers the complete sheet-metal process chain, supplying customers with highly complex parts and complete assemblies. “Providing good advice is an essential part of what we do,” says Jordi Batlle. With our punching expertise and efficient processes, we help our customers cut costs.”

Taking the right path together

Nobody expected the coronavirus pandemic – but it shows that the Batlles are on the right track with their smart factory. The crisis has encouraged them to continue with their hardware and software connectivity drive over the course of the coming year. They have also had a positive response from their employees, who are closely involved in the change management process. Some 75 employees work in the factory, each of them independently processing orders from start to finish. That gives them a greater understanding of the processes and the goal behind the optimization measures. It also fosters commitment and encourages people to take the initiative, says Batlle: “Dur employees are the key to our success. We all pull together when it comes to making improvements. Getting better at what we do is something we intend to continue, which is why we have already booked our next smart factory consulting session!”