You acquired four TRUMPF machines during the corona-virus crisis, a time when most other companies were reluctant to invest in costly machinery. What inspired you to make the purchase?

Mohamed Saleh: When the market hits rock bottom, it’s a good time to invest because things can only get better. Companies that do nothing during the crisis will eventually start looking for work. But when things improve, we want to be in a better position, ready to acquire a good share of the market and meet the market’s needs. You should never wait until a crisis is over to start investing. You might end up investing too late, and another crisis might hit by the time you are ready to act.

Sheet metal fabricators are increasingly turning to automation. For many companies, automation is the key to cost-effective production. How true is that for you?

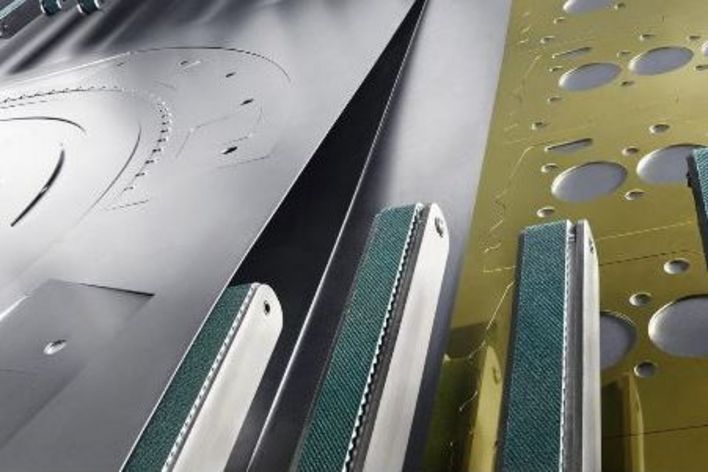

MS: Around five years ago, I started using simple automation concepts on some of my standard machines. That improved the ergonomics for the machine operators and helped speed up production. Those improvements encouraged me to buy machines in the future that include an automation option. Investing in automation also gives you more reliable results. For example, if you load or unload a machine without automation, you always run the risk of damaging the sheets. Another of my top priorities was keeping my machine operators safe. We actually need fewer operators now on our individual machines, so my employees have more time to focus on important production tasks.

Al-Ahmadeya was founded in 1987. Following in his father’s footsteps, Mohamed Saleh has known the industry since he was a child. The company has over 50 years of experience in the metal industry.

© Sayed Abd Algalil

Has your investment also had a measurable effect on indicators such as productivity? Do you have any concrete figures?

MS: We’ve obviously seen huge improvements in productivity. Looking back over everything we’ve produced in the past five years, I would say it has increased by around 300 percent thanks to automation.

What kind of products does your company specialize in?

MS: Our company specializes in processing and selling sheet metal products. We’re well-known for our car trailer parts. We also pro-duce storage tanks and car parts in high volumes.

When people talk about automation in sheet metal processing, their first thought is normally the big players in the US, China and Scandinavia. What is Egypt’s position in the international market?

MS: Egypt occupies a unique location that gives it a major role in the African, Arab and Mediterranean regions. The Suez Canal is an important hub for shipping, and Egypt itself is home to over 100 million people. It’s clear from all the ongoing investment programs with international businesses that we are a rapidly growing market. Al-Ahmadeya itself is one of the biggest sheet metal fabricators in Egypt. We’ve been working in metal forming and trading for many years, and now we’re investing in more new technologies than ever.

The Egyptian company Al-Ahmadeya and its 300 employees used the coronavirus hiatus to push ahead with their

long-term goal of automating all their processes. Thus they have seen huge improvements in productivity.

© Sayed Abd Algalil

How would you describe the Egyptian sheet metal processing industry?

MS: The sheet metal business in Egypt is the same as everywhere else. It’s dictated by market requirements, which is why much of the recent high demand has been in construction, for example.

One of the differences between the Egyptian market and the European markets is how we do business. In the past, most business in Egypt was based purely on spoken agreements and did not require written contracts. That’s changing now; we’re adapting and integrating into the international business world.

What are your long-term business goals?

MS: We have already invested in new production lines and added the new factory to keep our company growing. But our exact plans for the future are something I prefer to keep to myself (laughs). What I can reveal is that we are already working on some concrete plans and could well be looking at more subsidiaries in the future.

Thank you for talking to us, Mr. Saleh.