Laser welding systems and arc welding cells

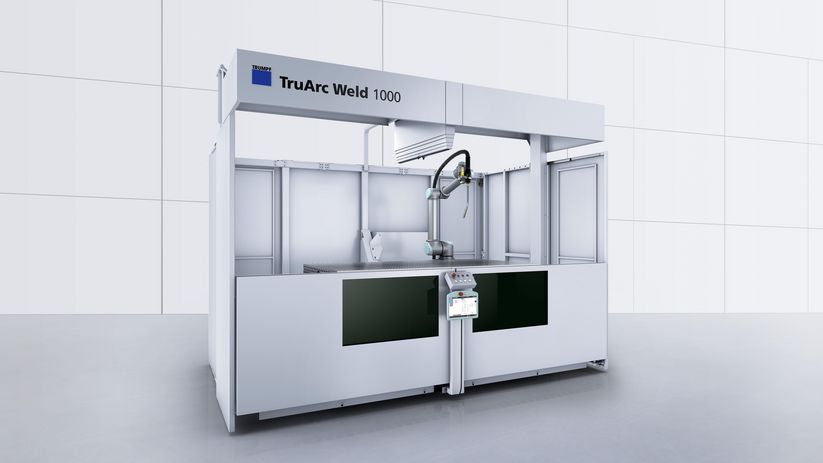

Laser welding systems from TRUMPF are the perfect tool for precision metal welding. They can be used to optimally join materials that have high melting temperatures as well as high heat conductivity. Thanks to quick programming and simple operation, the TRUMPF arc welding cell is ideal for getting started with automated welding. You benefit from higher productivity and quality compared to conventional manual welding.

With laser welding, you produce virtually distortion-free workpieces with the highest level of precision. Visually appealing weld seams require hardly any reworking. At the same time, our systems provide highly productive processes for large quantities with high repeatability or flexibility for changing lot sizes.

During arc welding, we use a special welding power source from Fronius for automated applications which also support the new modified pulse arc process PMC (Pulse Multi Control). In this way, the precision welding processes ensure the best results and quality.

At a glance: What are the advantages of our robotic welding cells?

A shortage of skilled workers and increasing quality requirements are major challenges faced by companies when it comes to welding. Find out here how robotic welding can help you.

Watch the live talk!

Get access to our live talk "The future of manufacturing: Laser welding at the highest level"

Find out all about automated laser welding with the new TruLaser Weld 5000! Experience the benefits of quick and easy programming, outstanding welding quality and integrated laser cleaning. Optimize your processes with innovative technologies and discover new possibilities in part design and processing strategies.

Would you like to find out how automated laser welding can make your production more efficient?

Welcome back!

We are activating our exclusive content for you.

We are checking your data.

Just one more step before you have access!

Many thanks for your interest in our exclusive content. Please open your email inbox and confirm your address. You will then have full access. Please check your spam folder as well.

Access not granted

Unfortunately you could not be registered for our exclusive content. Please email us at info@trumpf.com or use the contact form.

Unfortunately, an error occurred. Please try again later.