The range of variants is increasing, production sizes are decreasing: This is exactly where the TruLaser 8000 Coil Edition from TRUMPF comes into play. Sheet metal processors often use press lines for large series sheet metal processing, but have to manufacture bending tools for each new product variant: an expensive and time-consuming process. Processing with a laser directly from the coil saves time, costs and material. However, users of conventional 2D laser cutting machines also benefit from processing rolled-up sheets. In addition to higher material utilization thanks to tighter nesting and cost savings when purchasing coil material, the productivity benefits of laser coil processing are impressive.

Laser blanking

Laser cutting from coil is becoming increasingly important in numerous sheet metal processing industries – both for large manufacturers and job shops with medium to large lot sizes. But what exactly is laser blanking, and how can you also benefit from the highly productive, flexible coil system from TRUMPF?

What is laser blanking?

Laser cutting directly from the coil: The advantages

Coil, 2D laser cutting machines, press brakes: 3 blank production systems in comparison

|

| Icon Coil laser processing | Icon 2D laser cutting machines | Icon Press lines |

| Use | Medium to large series | Small series | Large series |

| Technology | Lasers | Lasers | Bending tools |

| Components | Simple to complex | Simple to highly complex | Simple |

| Advantages | Highly productive, economical, tool-free, and flexible | Also suitable for small lot sizes, flexible material thicknesses and types | Maximum productivity with consistent contour |

Coil, 2D laser cutting machines, press brakes: 3 blank production systems in comparison

|

| Coil laser processing | 2D laser cutting machines | Press lines |

| Use | Medium to large series | Small series | Large series |

| Technology | Lasers | Lasers | Bending tools |

| Components | Simple to complex | Simple to highly complex | Simple |

| Advantages | Highly productive, economical, tool-free, and flexible | Also suitable for small lot sizes, flexible material thicknesses and types | Maximum productivity with consistent contour |

These industries particularly benefit from laser blanking

Continuous adaptation of components, an increasing range of variants and the accompanying constant tool changes: this situation is now part of everyday work, and not only in the automotive industry. In many industries, there is also a trend towards smaller lot sizes. That's why TRUMPF experts have developed a solution enabling more and more industries to economically process sheet metal despite smaller lot sizes.

Learn all the details on our TruLaser 8000 Coil Edition – the highly productive, flexible laser blanking system for continuous trimming of coil material. We also demonstrate possible application examples for your industry.

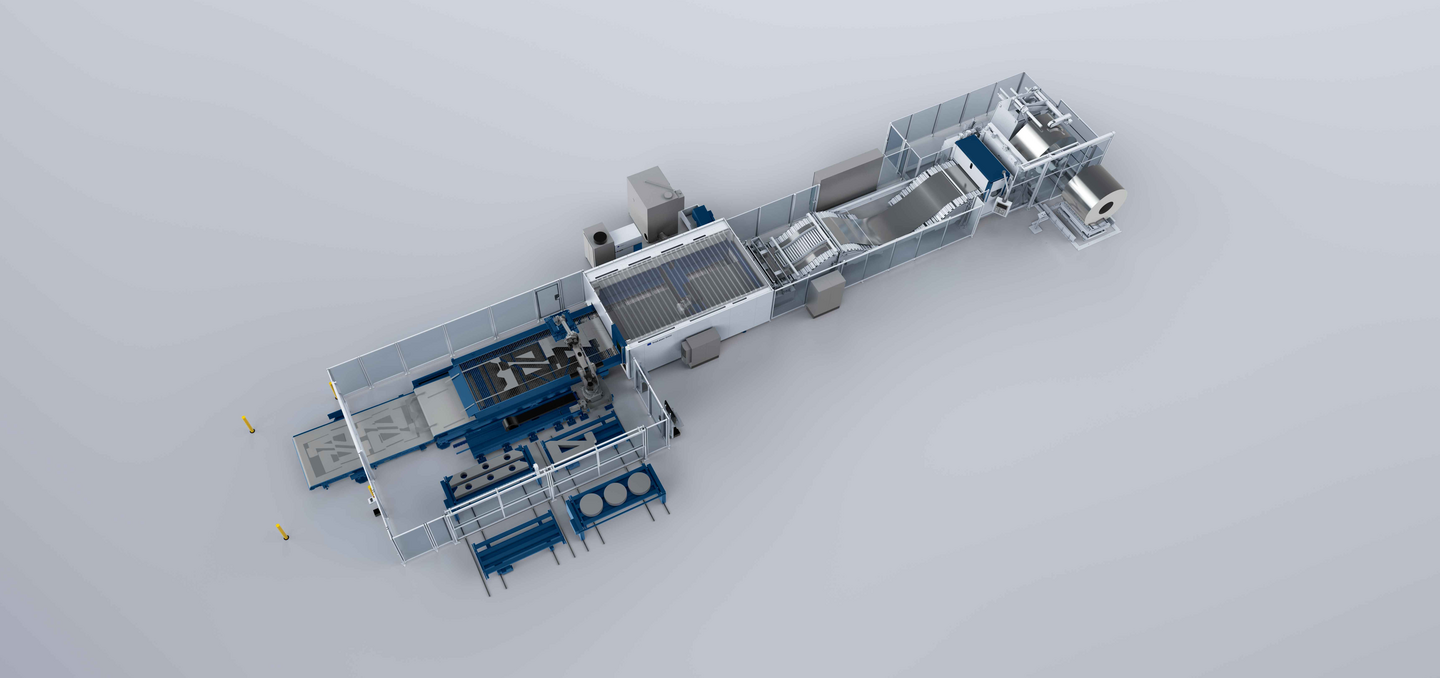

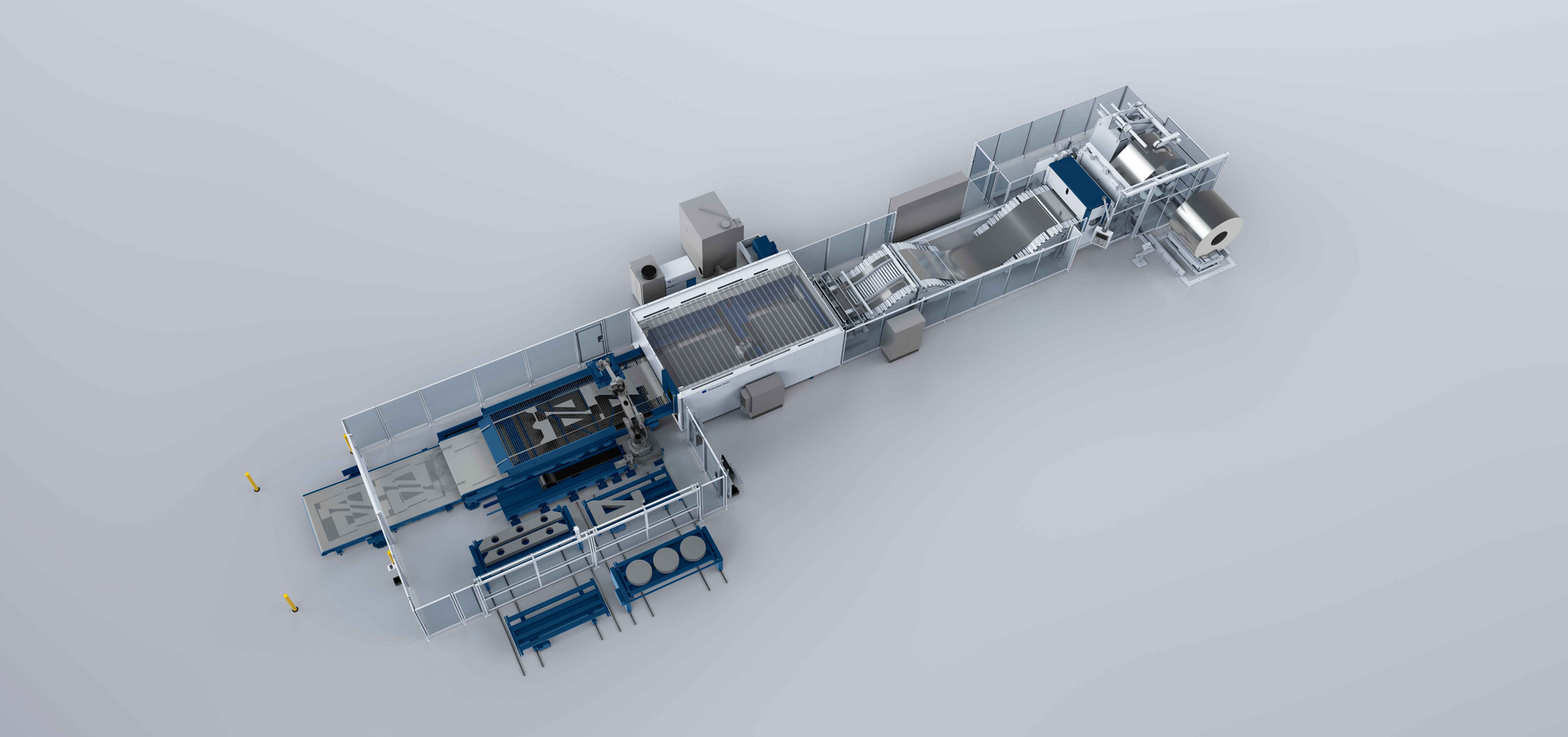

What does a laser blanking system look like?

The TruLaser 8000 Coil Edition by TRUMPF is the highly productive, flexible laser blanking system for continuous cutting of coil material. Equipped with an ARKU precision leveler, the ARKU belt system and TRUMPF laser combine for an entire turnkey system with many advantages for customers. Together with SIEMENS, an innovative control system has been developed – from coil unfolding, leveling, and laser cutting to fully integrated, robot-based component removal. The entire system programming up to robot removal is done by TruTops Boost.

At a glance: The coil-fed laser blanking system from TRUMPF

Decoiler

With short setup times and high availability, you benefit from high efficiency over the entire system service life. The system is characterized by compact design, high speeds, higher process reliability, and short coil changing times. Laser cuts can be optimally nested on strip material, reducing scrap. This saves you up to 15% on material costs. Whether steel, stainless steel or aluminum – many different materials can be processed. Coils up to 20 t can be accommodated as standard, 25 t and a width of 2150 mm are possible as options.

Precision leveling system

The CoilMaster 50 precision leveler from ARKU delivers consistently good leveling results for robust laser cutting. Coil material from 0 up to 4 mm in thickness is supported as standard, whether steel, stainless steel or aluminum. Even higher-strength steels can be processed with the nine leveling rollers. During roller leveling, the coil material passes through alternating bends, flattening it and relieving tension. The component can then be cut safely and then removed from the scrap skeleton.

Strip storage loop

The hydraulically controlled strip storage bridge supplies the laser cutting cell with material, decoupling the material feed cutting process and the strip system. The belt speed in the strip system is reduced to a minimum, but never stopped. This avoids the risk of surface damage to the strip. The strip feed rollers integrated in the strip storage transport the strip material to the laser cutting cell at up to 40 m per minute.

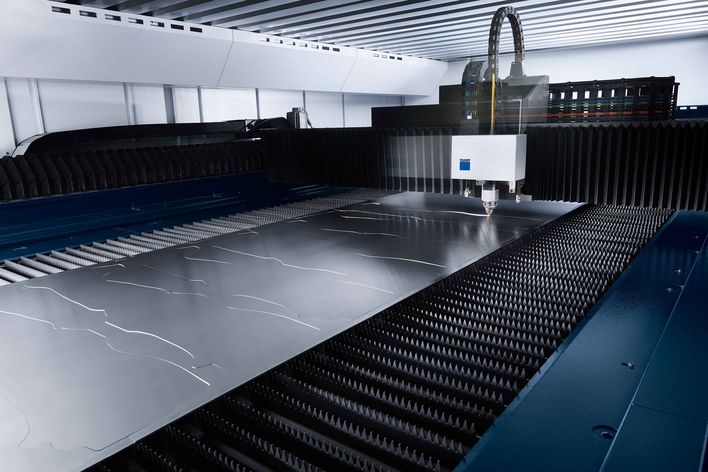

TruLaser cutting cell with TruDisk, including conveyor belt

The heart of the laser blanking system is a proven TruLaser cutting machine. The coil material is transported linearly through the machine, reducing non-productive times by a factor of up to 2.5. This is made possible by a support belt newly developed by TRUMPF. While the new material is transported in, the processed material – including scrap – simultaneously moves out. This increases the entire system productivity many times over.

Automated robot unloading

One or, optionally, two robots enable parallel to production unloading and repeatable stacking. The complete integration of the robot kinematics into the control architecture eliminates the need for robot-specific programming expertise. The position of the components is already determined during programming or nesting of the cutting parts in TruTops Boost. This way, the robot immediately knows where the components to be removed are located.

Scrap disposal

Small separating cuts are already made in the scrap skeleton during the cutting process. In this way, the scrap skeleton breaks into smaller pieces during removal and can be disposed of in a cost-efficient manner. The scrap conveyor can transport scrap out of the machine in three directions as required - either directly out or via a transverse conveyor belt to the left or right. This way, scrap removal can be integrated into the customer's scrap logistics.

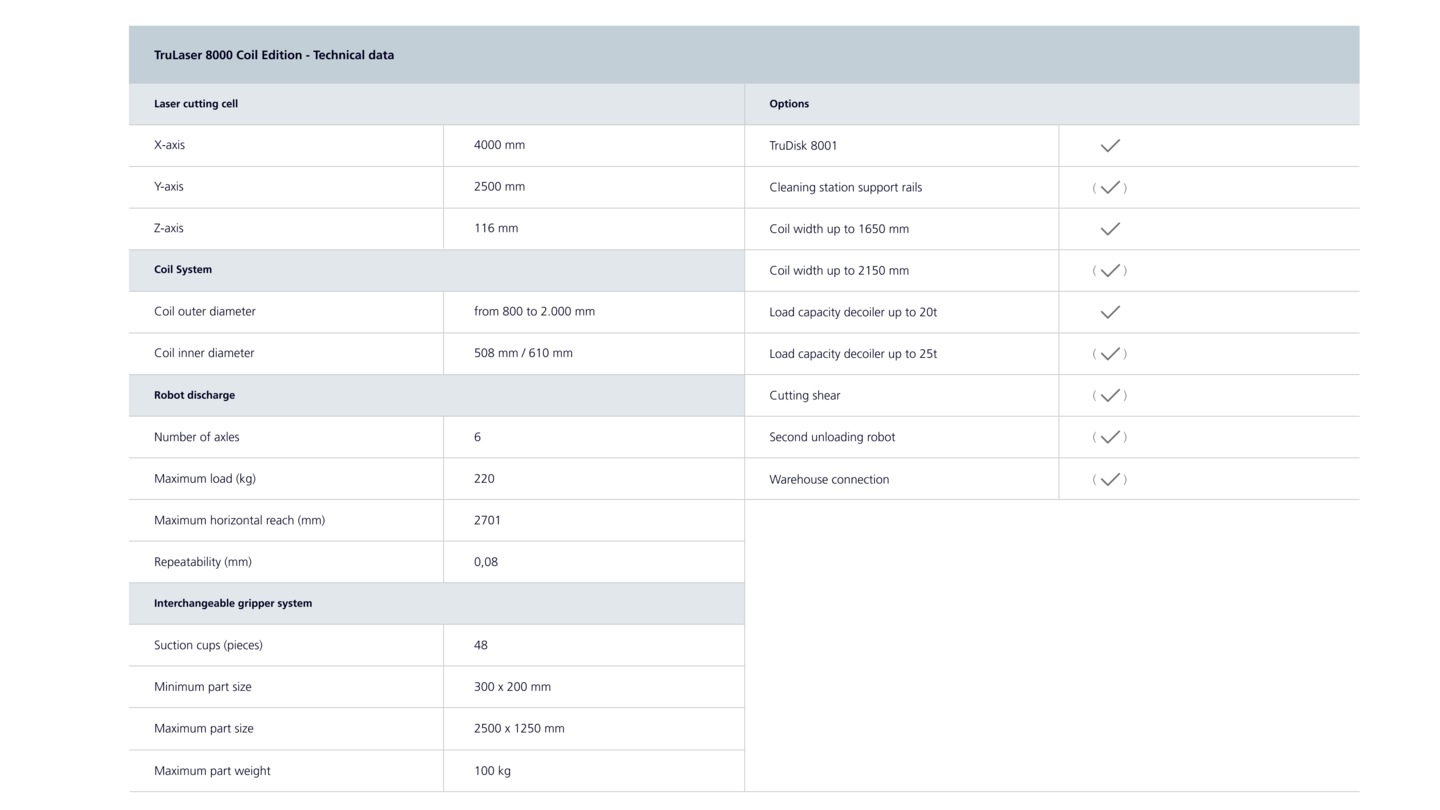

TruLaser 8000 Coil Edition - Technical data

The technical data as a download

In practice: For which applications is a coil-fed laser blanking system suitable?

Not only is TruLaser 8000 Coil Edition ideal for sheet metal processing job shoppers with larger lot sizes, but the laser blanking system from TRUMPF also plays to its strengths in many applications for high-volume manufacturers.

Was your application not mentioned? We would be happy to advise you!

Would you also like to cut from coils and profit from tool-free laser cutting? We would be happy to advise you for a specific laser cutting solution. Just get in touch with us.