Panoramic windows, elevated seating and plush semi-reclining chairs may sound like the description of a luxury hotel suite. But it actually refers to the upper deck of the premium double-decker Avante H8 Grand Captain, the flagship model in Tentrem’s range of luxury coaches.

The vehicle-body manufacturer specializes in crafting custom bus bodies on chassis from renowned brands like Mercedes-Benz, Volvo and Scania, while also producing intercity buses that serve routes across Java, Bali and other islands in Indonesia. Managing director Yohan Wahyudi aims to make Tentrem into Indonesia’s premier bus manufacturer. His vision hinges on getting the right balance between two seemingly contradictory goals: customization and standardization. He is determined to optimize production efficiency, but customers must still be able to access unique, tailored products. “By providing our employees with new machinery and suitable software, we help them instill creativity and innovation in their work,” he says. Quite an achievement for a company that started out so small.

Growth through transformation

Tatang Wahyudi, Yohan’s father, founded Tentrem in 1983 as a bus operator in Malang on the island of Java. In 1986, he opened a repair workshop to maintain his fleet. His mechanics fixed scratches and dents, getting buses back onto the road by handcrafting body panels and welding components under open-air corrugated shelters. Over time, Tatang’s business became more and more successful, and the workshop began servicing external clients a year later. The bus operator still exists to this day, and the company was officially established in 1991 as PT Tentrem Sejahtera, or Tentrem for short. “We kept growing and gradually transitioned from repairs to designing our own bus bodies,” Yohan recalls.

Today, the original tin-roofed sheds have been replaced by modern production facilities. An elegant glass-fronted administrative building occupies a prominent position near the main road, backed by an almost eight-hectare complex of production halls. All in all, Tentrem employs more than 600 people. Yohan Wahyudi keeps a close eye on the business, and is known for his systematic and data-driven approach to management. Before joining the family firm, he studied computer science in Canada and completed an MBA in China. Today, he strives to introduce greater speed, efficiency and precision into the company’s production processes. “In the past, clients brought us sketches, and we painstakingly shaped the metal sheets to match,” he says. The problem was that most of the repairs had to be carried out by hand. And whenever they needed a replacement part for a badly damaged bus, the workers found themselves back at square one. “Nowadays, we try to automate as much as we can. The trick is to get the right balance between standardized products and customized solutions,” says Wahyudi

Accelerating ambitions

Tentrem has seen a further surge in growth under Yohan’s leadership. But this growth poses its own set of challenges: customers put in larger orders, and Yohan is keen not to disappoint them. His goal is to transform Tentrem into an original equipment manufacturer (OEM), producing consistently high-quality bus bodies in reliable quantities. “We want to match the standards of established OEMs,” Wahyudi says. “To do that, we need a proper pro duction line, efficient schedules and clear daily targets. The biggest challenge for my generation is changing the mindset around manual labor.”

The transformation began in 2015 when the family discovered TRUMPF at a trade fair. At first, Yohan’s father, Tatang, was skeptical about spending large sums on advanced technology and automation. He felt that processing body parts wasn’t complicated enough to justify such a step. But after a strong financial year, the family decided to take the leap. “We stepped out of our comfort zone and invested in new technology,” Yohan says. That year, they purchased a TruLaser 3030, making Tentrem a pioneer in sheet metal processing in Indonesia.

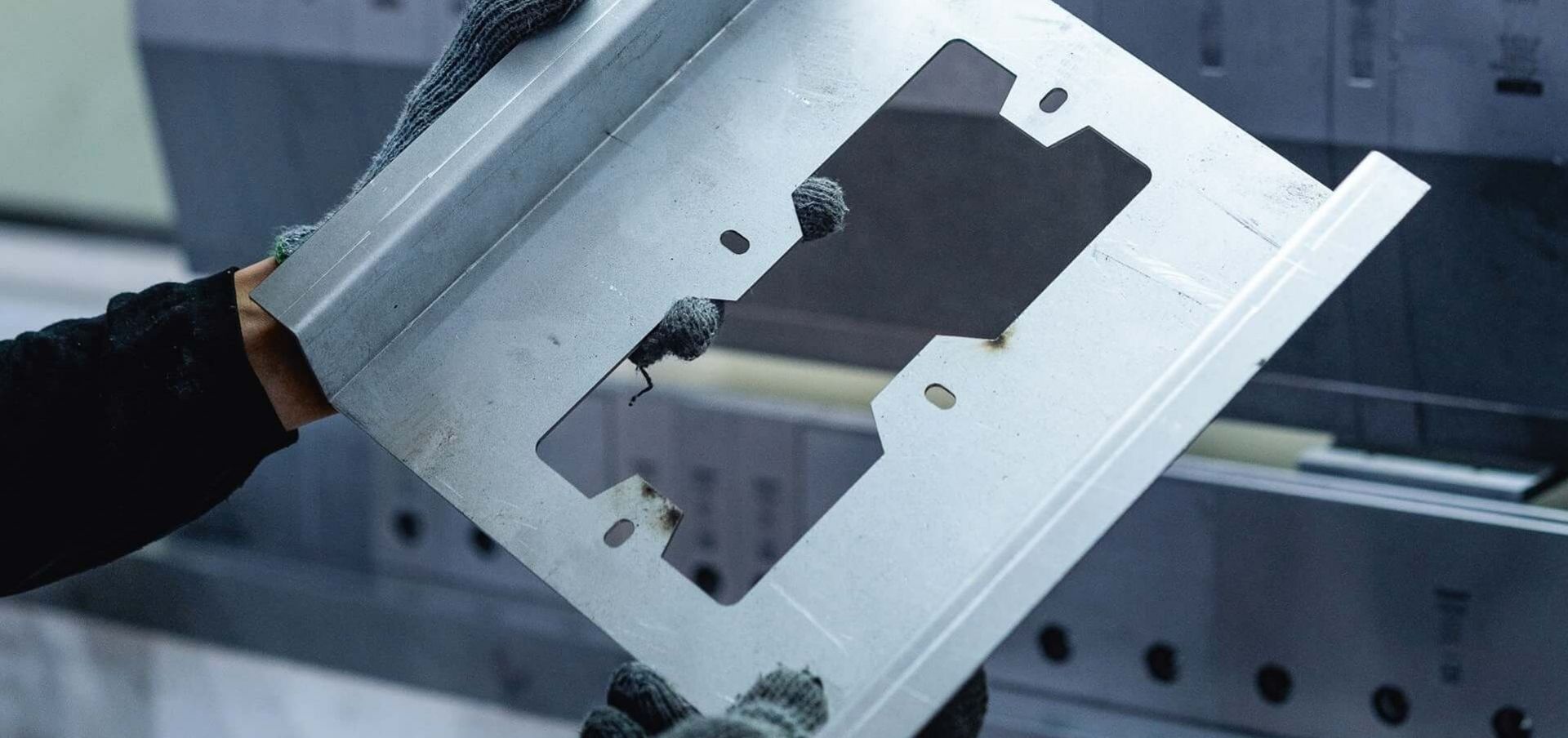

“We immediately saw the benefits of automation for things like the baggage compartments,” says Yohan. Previously, employees needed five or six separate parts to build a baggage compartment door. Nowadays, they take a single sheet of metal, cut it with the TruLaser 5030, and shape it with the TruBend Center 5030. “This new approach eliminates welding entirely, much to the amazement of our customers!” says Yohan.

Next year, Yohan plans to invest in TRUMPF’s Oseon software. “A bus consists of thousands of parts. If we can make our pro duction more efficient, we’ll save time and money. That’s where Oseon comes in,” he says. “It feels like 2015 all over again, before we bought our first TRUMPF machine. We know what the technology can do, it’s just a question of learning to make the most of it.” The consistent quality offered by TRUMPF machines has a wide array of benefits.

“It allows us to oversee the entire production process, so we can prioritize which parts are needed most urgently and which can wait,” Yohan explains. “We can also optimize the design of each part by using innovative design formats and manufacturing technologies. That makes the process simpler and reduces costs – similar to what we experienced with the baggage compartment door.”

For Yohan, innovation is synonymous with efficiency. It’s about offering a standardized production process that remains flexible enough to accommodate individual customer requests. In the double-decker Avante H8 Grand Captain bus, for instance, semi-reclining seats are the premium choice – but customers can also opt for extra rows of standard seats instead.