Solutions

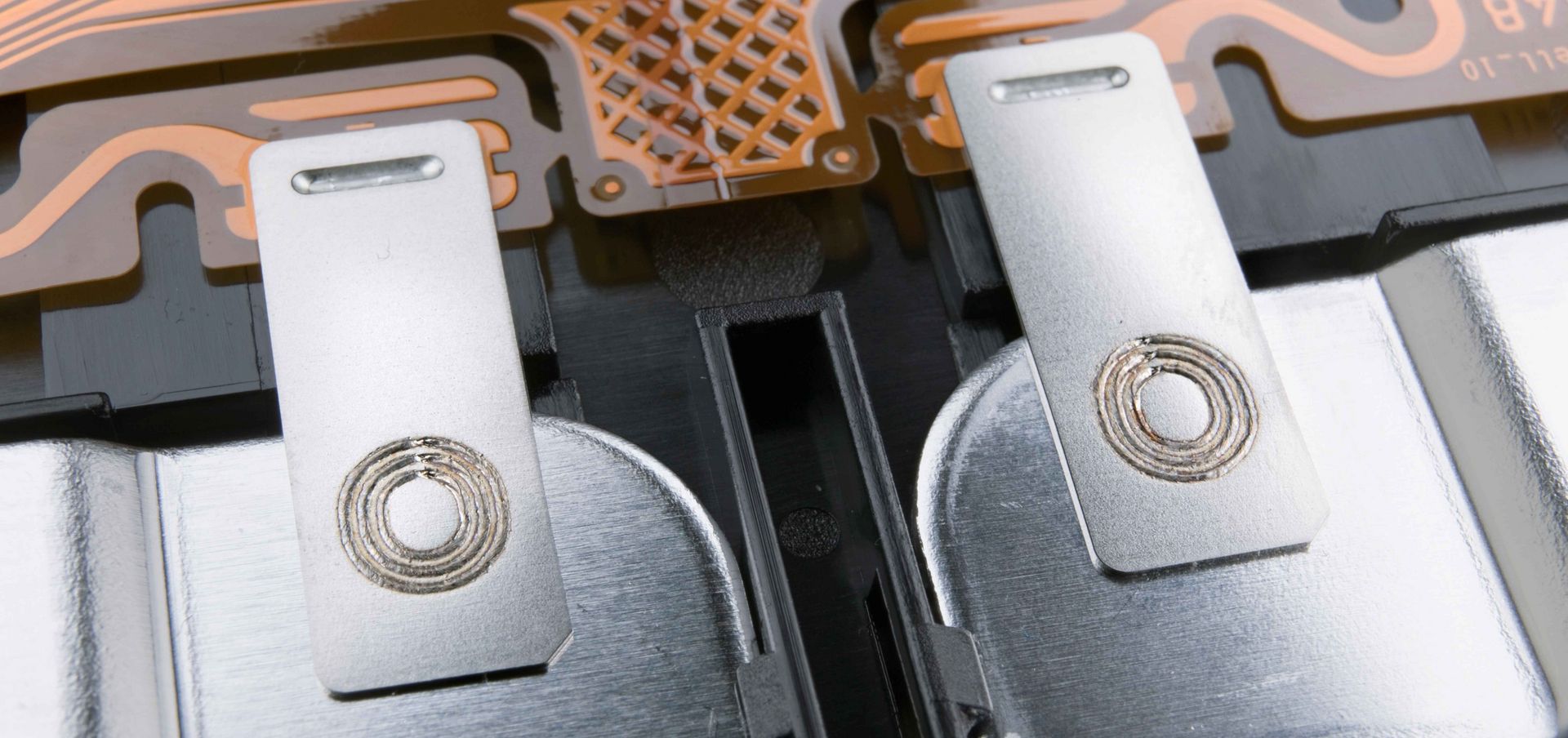

During a visit to the TRUMPF Laser Application Center, Daniel Weller becomes aware of a new development in the field of detection systems. "Up until now, we worked with TRUMPF's VisionLine Detect image processing, which helped us a lot with processing conventional Cell Contacting Systems (CCS)," states Daniel Weller. However, with the cloud-based EasyModel AI training platform, TRUMPF raises the bar even further: the combination of EasyModel AI and the KI Filter option for TRUMPF VisionLine Detect image processing recognizes variable environmental conditions, component reflections, changing lighting situations and fluctuations in material properties. "Shortly after TRUMPF's EasyModel AI became officially available, we were awarded the contract for a complex cell contacting system that presented us with major challenges, measuring two meters in length and featuring 50 welding positions. EasyModel AI came at exactly the right time," says Weller.

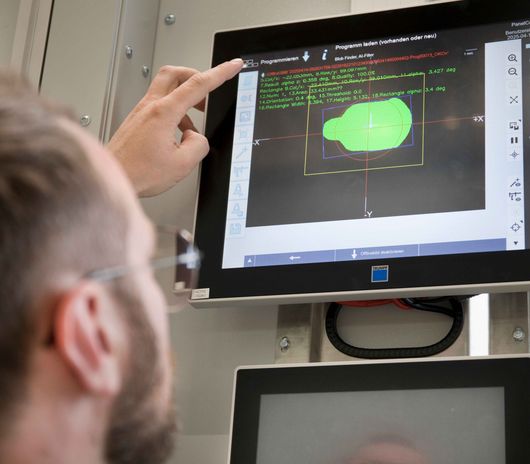

EasyModel AI is a tool which allows even users without programming knowledge to easily create and train their own image-based AI models tailored specifically to components. "As the first step, we use VisionLine Detect to simply record images of those segments of the component on which welding positions must be set. The images are stored with us using Quality Data Storage and we can then upload them into EasyModel AI, which we can simply access via our MyTRUMPF platform," explains Weller. Once a project has been created, Weller and his colleagues mark the welding positions to be detected on the images and the AI starts evaluating and calculating a model. This can be optimized intuitively by the operator piece by piece. Only a small number of training images suffice for a functioning AI model. Once a satisfactory model is available, it is transferred to the production line. There, the AI Filter option for VisionLine Detect is used. The filter accurately distinguishes between relevant image areas and areas such as fixtures, soiling or reflections. "The difference between VisionLine Detect with and without an AI filter is particularly clear here," says Weller explaining further. "The AI filter binarizes the image - i.e. it creates a display in black and white only. The detected component is displayed in white, while the surrounding areas are displayed in black. This allows the edge detection algorithms to easily identify the welding area to be detected." Previously, Weller and his team used VisionLine Detect image processing with position-dependent lighting. This was deliberately varied in order to reliably detect the respective positions. The process had to be individually adapted to the respective position in the processing field to compensate for the different reflections of the component surfaces. The process was time-intensive and dependent on numerous influencing factors – additionally, it had to be carried out separately for each component position.

Implementation

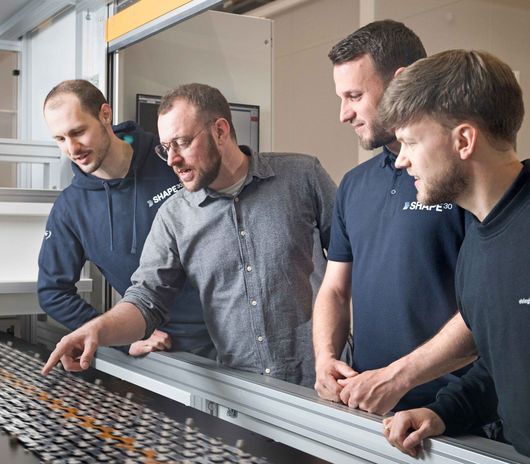

To implement the new solution, ElringKlinger simply had to activate the EasyModel AI option with AI Filter and complete a short introductory phase. "The TRUMPF employees guided us through all the process steps directly on the component during commissioning the pre-series plant," explains Weller. "After one or two hours, we had completed our first component." If there are any uncertainties these days, TRUMPF experts simply respond to these remotely or in Teams meetings. The cooperation is facilitated by Quality Data Storage by TRUMPF. Data can be stored there and shared with TRUMPF specialists as required.

For Weller, the simplicity of the training process counts as one of the main advantages of EasyModel AI: "For good results, we no longer need days, but hours." It is also important that no prior knowledge is required to achieve good results. "This becomes particularly important once the series has started and our less experienced colleagues at the various locations need to make minor adjustments. The system works according to the 'what-you-see-is-what-you-get' principle. This is easy to understand even for non-programmers," says Weller. The option to carry out smaller adjustments is also an advantage for him and his colleagues: "Every CCS is designed differently but sometimes the differences are only minimal. Using AI, we are now able to use existing training images of CCSs as a basis for new models, by simply retraining minor deviations. This further speeds up the development phase."