The perfect entry into punching: fast and versatile – for small to medium formats

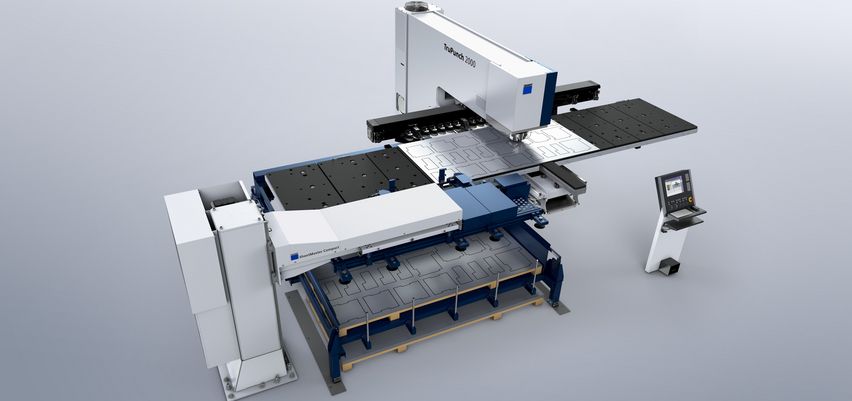

The TruPunch 2000 is the compact punching machine for companies that want to start using automated punching technology economically or react flexibly to peak loads. With a punching force of 165 kN, up to 900 strokes per minute and an electro-hydraulic drive, it reliably processes a wide range of parts - efficient even at low workloads. Its open design and part removal of 180 × 500 mm offer optimum access, even for large formats. Compared to classic turret machines, it scores with short setup times and high flexibility. Can be optionally automated with the SheetMaster Compact for a continuous material flow in multi-shift operation.

For an economical start or to cover capacity peaks.

High productivity with low operating and setup times.

Open design and large part removal for convenient handling.

Expandable at any time with SheetMaster Compact for more speed and safety.

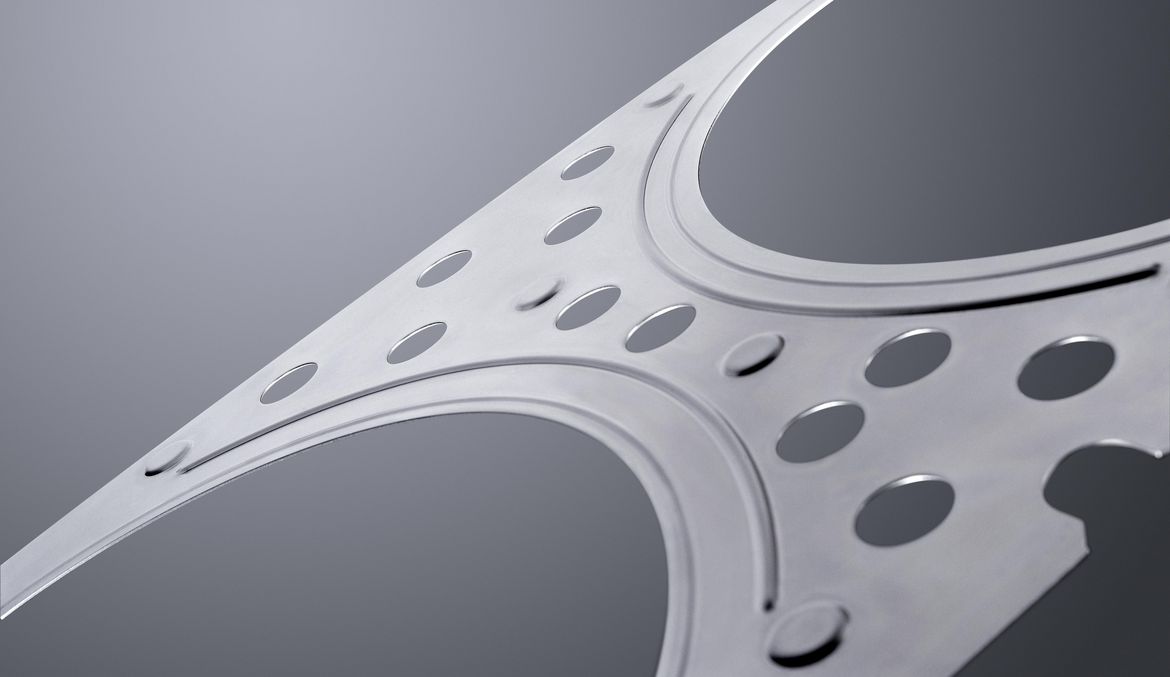

Electronic component

Produce with flexibility using tools for every application, for example, flanges, cups, roller folding. For this component, the following tools were used: step tool, bracket tool, cup tool rectangular and round, offset roller tool, and pinching roller tool.

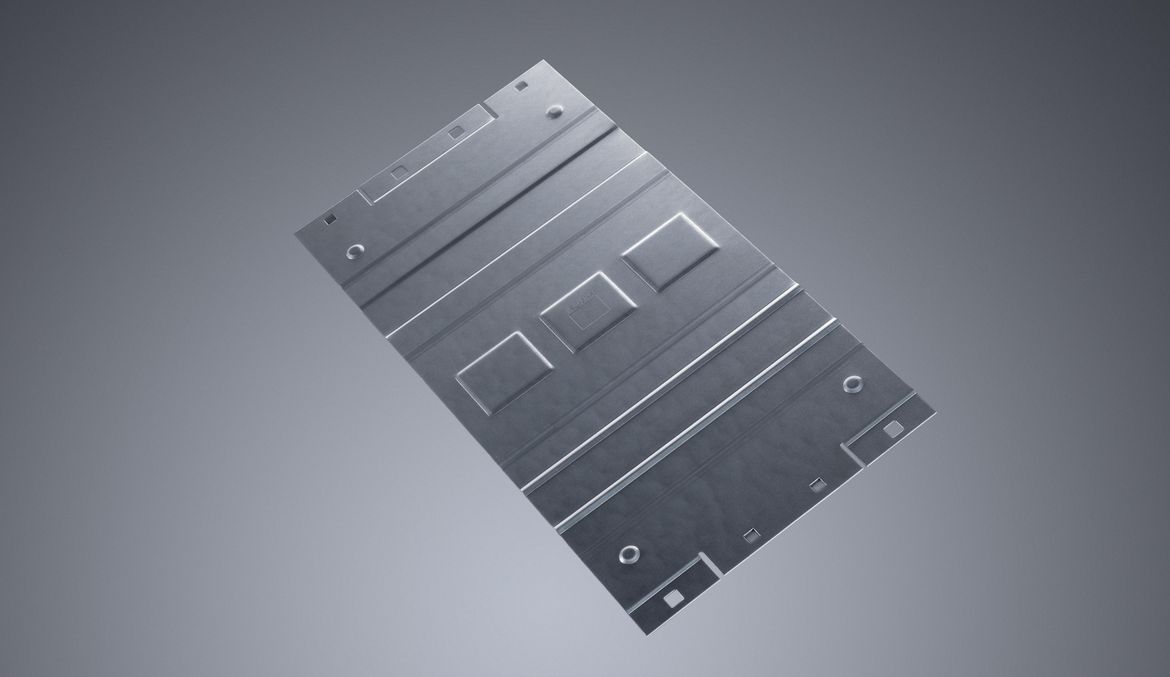

Workpiece

With the largest tool range in the world, the machine offers the highest level of processing flexibility. For this workpiece, the following tools were used: roller beading tool, MultiCut tool, cup tool, and roller offsetting tool.

|

TruPunch 2000 medium format

|

|

|---|---|

| Dimensions | |

| Width | 6540 mm 1 |

| Depth | 7237 mm 1 |

| Height | 2155 mm 1 |

| Maximum stroke rate | |

| Punching (E = 1 mm) | 900 1/min |

| Marking | 1600 1/min |

| Working range | |

| Punching mode, X axis | 2500 mm |

| Punching mode, Y axis | 1250 mm |

| Maximum sheet thickness | 6.4 mm |

| Maximum workpiece weight | 150 kg |

| Maximum punching force | 165 kN |

| Tools | |

| MultiTool tool changing time | 2.4 s |

| Number of tools/clamps | 18 pieces / 2 pieces |

| Part removal | |

| Maximum part size, part removal flap, punching | 180 mm x 150 mm |

| Maximum part size, part removal flap, punching (with moving table) | 180 mm x 500 mm |

| Maximum part size, fixed chute, punching (with moving table) | 460 mm x 500 mm |

| Consumption values | |

| Average power input of active auto-shutdown | 0.3 kW |

| Average power input in production | 4.5 kW |

The TruPunch 2000 stands for quality and efficiency at the highest level. Material-friendly processing and handling are ensured, as well as energy-efficient and resource-saving production.

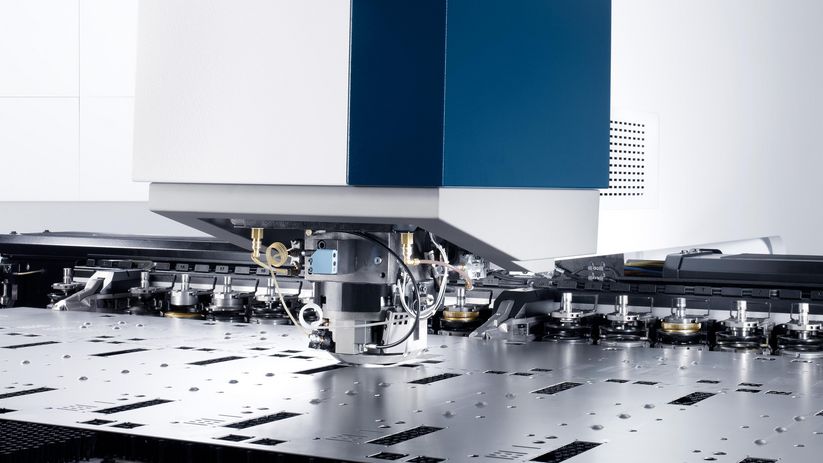

Brush tables are available for gentle material handling.

With the blank processing package, you can also process blanks simply and in a process-reliable way. This is made possible by a second index pin and additional clamp, amongst other things.

As a result of the On-Demand Drive, the hydraulic punching head system always works to the optimum level. This leads to reduced noise generation during non-productive times and reduces the hydraulic load of the entire system.

TRUMPF is the first manufacturer worldwide to offer punching machines that feature skeleton-free processing. This innovation saves material and increases process safety.

TruTops Boost

Construct and program your laser, punching, and combination punch laser machines intelligently with TruTops Boost, your all-in-one 3D solution. Numerous automated processes save you time-consuming routine processes and the joint nesting pool saves time and material. You also always have an overview of all manufacturing orders and order-based work.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF combines the software intelligently with machines and services to create customized Industry 4.0 solutions for your Smart Factory.

Produce threads on the punching machine using a chipless procedure. Due to the complete processing on one machine, you can reduce your part costs.

With the roller offsetting tool you can add straight and curved steps of any length to the sheet. It works at a very high processing speed.

Using the engraving tool you can mark sheet metal parts in path mode with flexibility. The non-cutting processing ensures results of the highest quality.

TRUMPF offers the world's largest range of punching tools on the market. You will find the perfect solution for every punching and forming application.

The SheetMaster Compact is the space-saving and affordable entry level solution for the automation of your TruPunch 2000.

Loading and unloading

The SheetMaster Compact takes over the process-reliable loading of sheets as well as the unloading of microjoint sheets and scrap skeletons. In this way, the machine operates completely automatically, if required. This increases productivity and also relieves the strain on the operator.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- The dimensions are approximate; the dimensions specified in the installation plan are valid.