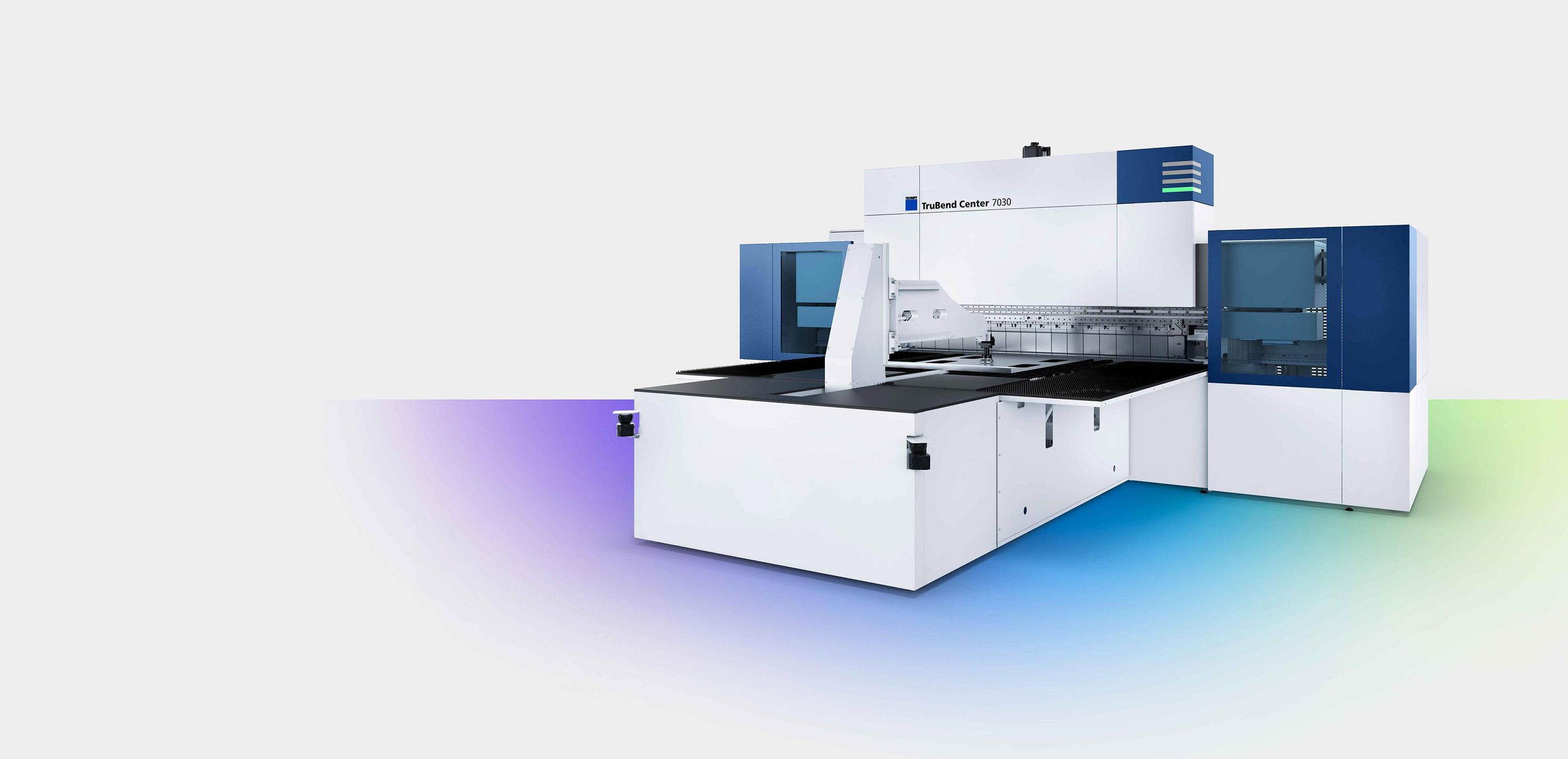

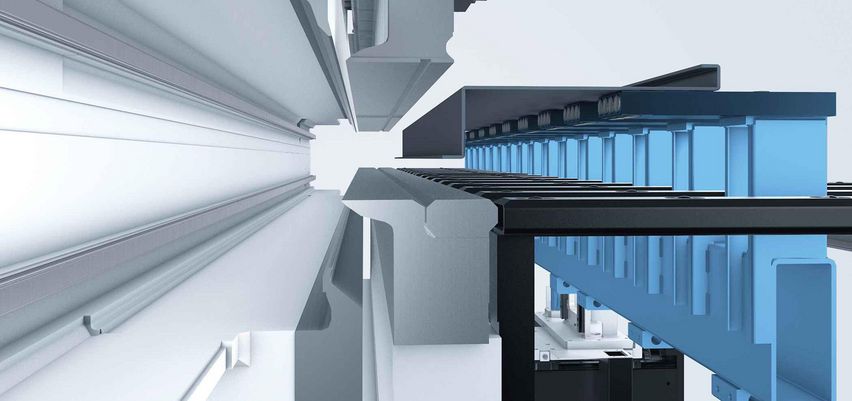

Fully automated bending perfection - for complex sheet metal parts and maximum productivity in the Smart Factory

Imagine a production process in which every challenge becomes an opportunity: complex shapes are created effortlessly, perfect surfaces are a matter of course and short cycle times are standard. The TruBend Center Series 7000 sets new standards in panel bending – the process enables mark-free bending for flawless results and offers maximum flexibility for changing lot sizes, materials and tasks. Precise and efficient processes are guaranteed, while intuitive automation eliminates uncertainties and makes it easy to get started – without any hurdles. The system can optionally be integrated directly into interlinked production lines, thus increasing the efficiency of your production. Because automation is the future.

Because automated material handling, flexible gripper systems and tool changers and a wide range of software enable networked, automated processes.

Because the fully automatic manipulation of the parts, and fast edge direction changes enable maximum efficiency and short cycle times.

Because intuitive operation and simple offline programming with the TRUMPF TecZone Bend software make even complex sheet metal parts accessible.

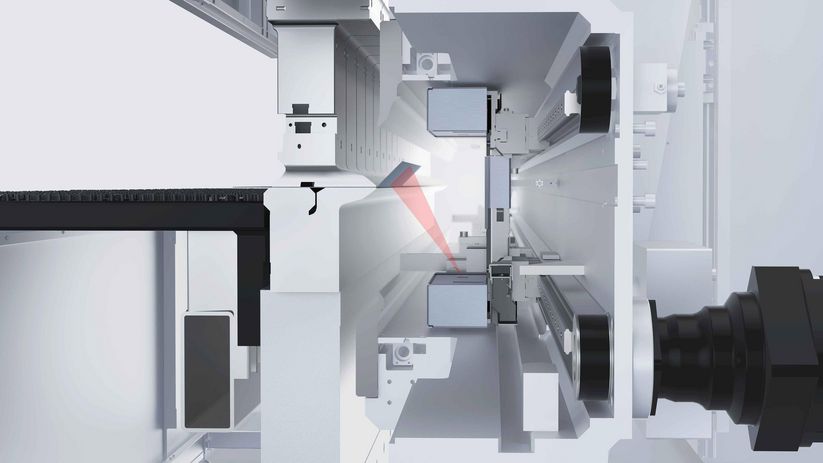

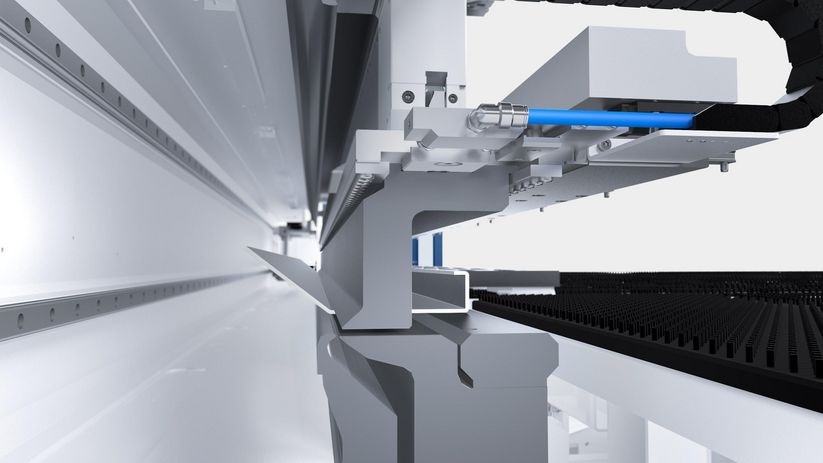

Because the patented angle sensor ACB laser automatically corrects every bend, ensuring high part quality in the long term.

Because fast solutions count in everyday production, technical support, targeted training and high-quality TRUMPF bending tools ensure smooth processes.

Mild steel drawer, sheet thickness 0.6 mm

High repeatability for complex shapes and large series.

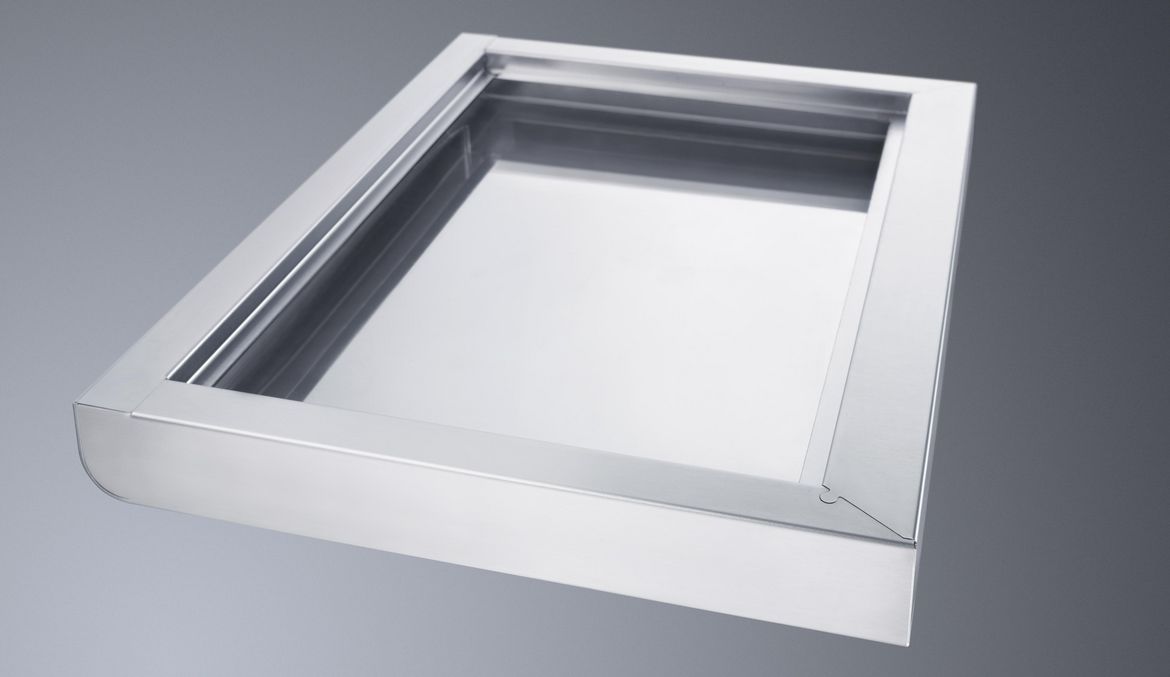

Mild steel housing cover, sheet thickness 0.12 in.

All angles can be bent with the usual precision and reliability, even with thicker sheets.

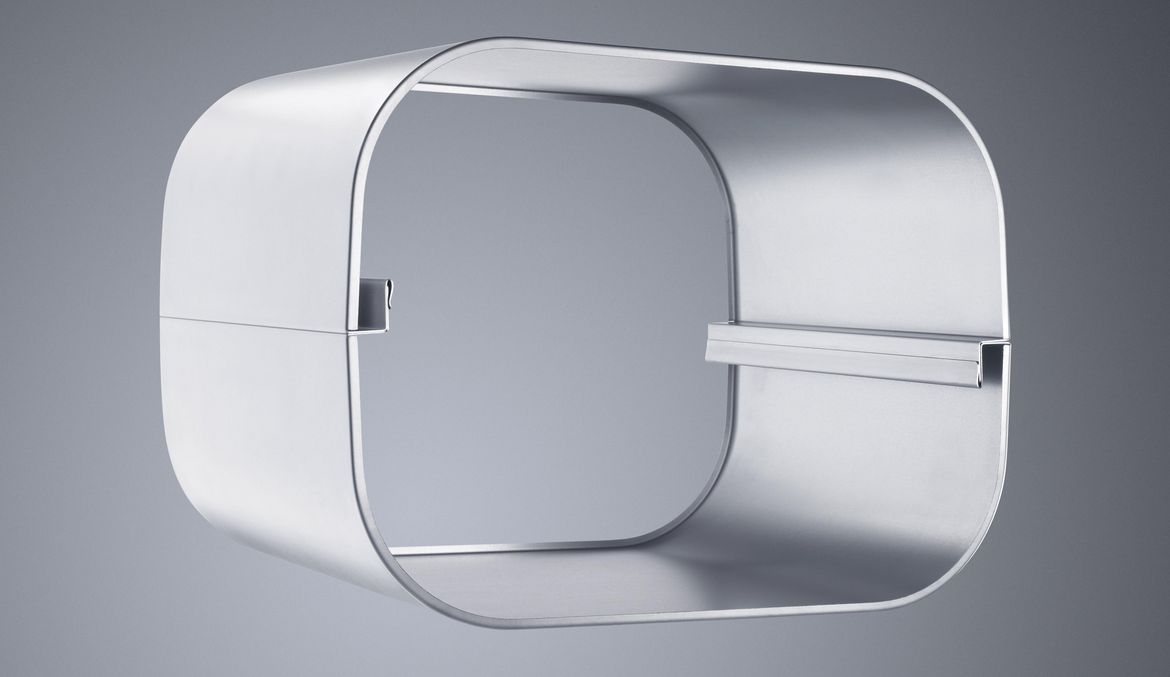

Stainless steel drawer, sheet thickness 0.04 in.

Radius bending with double sheets – extra stability with the same sheet thickness.

Stainless steel screen trim, sheet thickness 0.04 in.

Special studs enable the components to be easily clicked together – ideally prepared for subsequent laser welding.

Column cladding made of mild steel, sheet thickness 0.8 mm, consisting of 2 parts

Innovative connection options are made possible by the high level of precision.

Mild steel guard plate, sheet thickness 0.04 in.

Surface-friendly bending ensures that even sensitive or coated sheets remain free of marks or scratches.

|

TruBend Center 7020

|

TruBend Center 7030

|

|

|---|---|---|

| Machine | ||

| Maximum bending length | 2163 mm | 3123 mm |

| Minimum bending length | 200 mm | 200 mm |

| Maximum box height | 350 mm | 220 mm |

| Maximum part size | 2160 mm x 1500 mm | 3120 mm x 1500 mm |

| Maximum part diagonal | 2640 mm | 3460 mm |

| Minimum bending depth (standard tool) | 145 mm | 145 mm |

| Min. Biegetiefe (einschwenkbares Niederhalterwerkzeug) | 30 mm | 30 mm |

| Max. Materialdicke Stahl | 3 mm (400 MPa) | 3 mm (400 MPa) |

| Maximum material thickness, stainless steel | 2.2 mm (700 MPa) 2 | 2.2 mm (700 MPa) 1 |

| Maximum material thickness, aluminum | 4 mm | 4 mm (265 MPa) |

| Minimum material thickness | 0.4 mm | 0.4 mm |

| Anschlussleistung | 53.4 kVA | 80 kVA |

| Durchschnittliche Leistungsaufnahme | 10 kW | 15 kW |

| Geräuschpegel | 73.4 dB | 78.8 dB |

| Betriebssteuerung | Windows Embedded Standard 10 | Windows Embedded Standard 7 |

| Loading cart with storage connection | ||

| Maximum sheet size | - | 3050 mm x 1525 mm |

| Max. loading cart load | - | 3000 kg |

| Loading height incl. pallet, floor-mounted version | - | 179 mm |

| Loading height incl. pallet, flush-mounted version | - | 179 mm |

| Loading and unloading unit | ||

| Suction area folded in (suction cup) | - | 120 mm x 220 mm |

| Suction area folded out (suction cup) | - | 120 mm x 1100 mm |

| Max. blank size | - | 3120 mm x 1600 mm |

| Min. blank size | - | 300 mm x 200 mm |

| Dimensions, weights | ||

| Length | 5200 mm | 6490 mm |

| Width | 4855 mm | 5327 mm |

| Height | 3326 mm | 3345 mm |

| Maschinenhöhe (Niederhalter) | 3328 mm | 3270 mm |

| Min. hall height | 4260 mm | 4300 mm |

| Weight | 21500 kg | 31600 kg |

The TruBend Center Series 7000 is the automated flagship in panel bending and stands for maximum flexibility, precision and efficiency. Panel bending enables economical, mark-free processing, even of complex sheet metal parts – with particularly short cycle times. This makes the series perfect for the highest demands in terms of quality, productivity and speed.

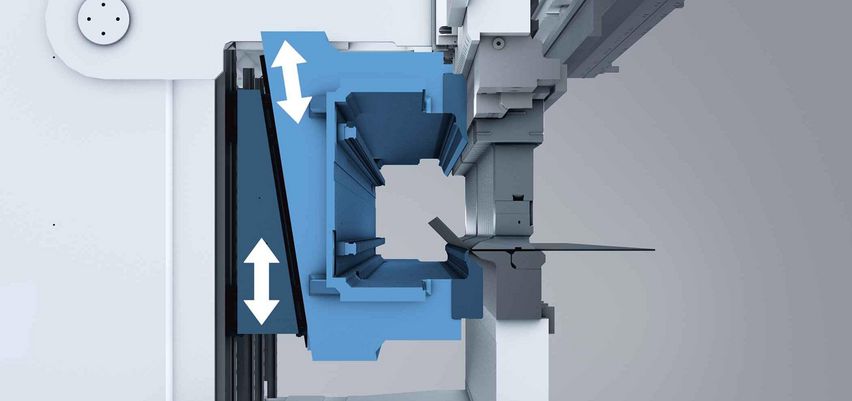

The ACB Laser ensures maximum precision and repeatability during bending without any reworking. The optical system detects the exact angle without contact and corrects it in real time. This reduces sources of error and rejects, no matter how complex the component is. Decision-makers benefit from consistently high part quality and lower costs, while operators can rely on an automated, reliable process.

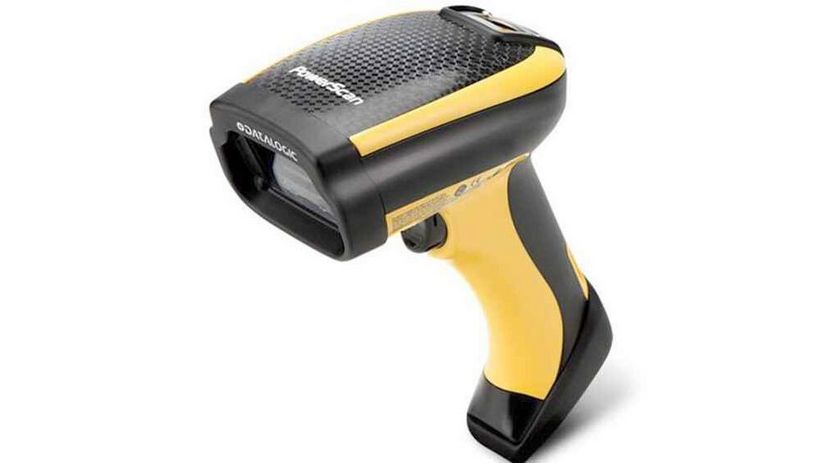

With the 2D code or Bluetooth scanner, the suitable bending program can be loaded in no time at all. This speeds up work preparation, minimizes errors and ensures a smooth production start – even in the case of frequent program changes.

An additional screen on the control unit enables parallel programming and paperless working directly at the machine. All important information is available at a glance – for efficient and transparent processes. This avoids duplication, media disruptions and loss of information in day-to-day production.

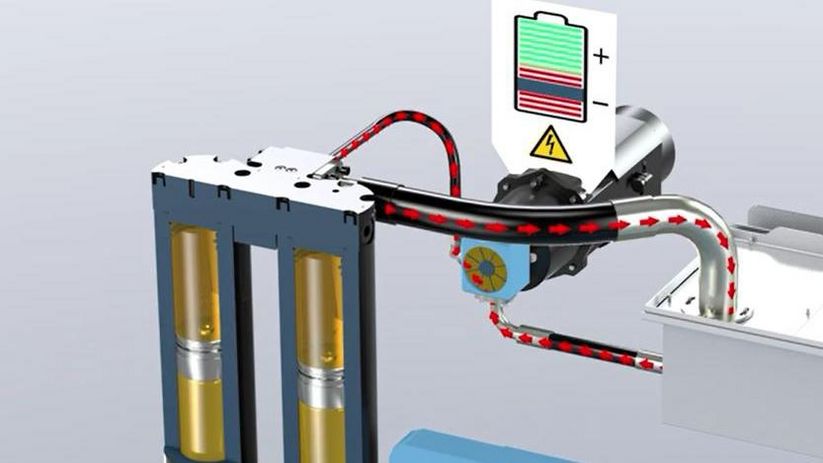

The On-Demand Drive supplies your TruBend Center machine with the exact amount of energy required – it only runs during the bending process, otherwise the hydraulics stand still without consuming any energy. The system works particularly economically, quickly and very quietly – and at the same time ensures low operating costs and a pleasant work environment.

The optional magnet or gripper module is part of the 2-axis part manipulator and can reliably handle components where conventional suction cups reach their limits. Even the smallest or most complex shaped parts are handled safely, reducing waste. This maintains process reliability and flexibility in production – independent of the component geometry.

The optional 3-surface suction module of the 2-axis manipulator ensures safe, flexible part handling – even with challenging bending geometries and small suction surfaces. The parts are manipulated using one of the 3 available suction surfaces. This ensures maximum process reliability and reduces operating effort and potential sources of error.

The TruBend Center Series 7000 can be seamlessly integrated into existing software landscapes and monitoring tools. Thanks to open interfaces, connections to third-party systems are also possible. This allows you to avoid siloed solutions, maintain an overview of all production processes and react flexibly to new requirements in networked production.

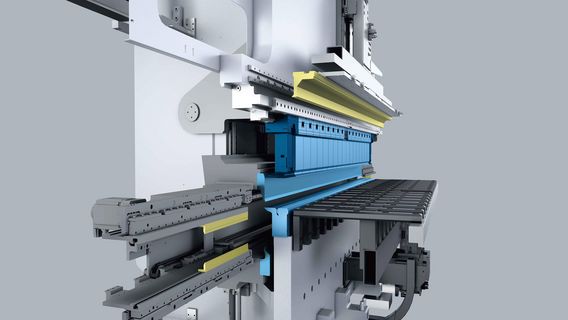

The TruBend Center 7030 ENW automatic tool clamping optimizes the process when changing ENW tools, increases process reliability and boosts the efficiency of the entire automation system. This effectively solves problems caused by manual clamping processes, such as loss of time or operating errors.

With the TruBend Center 7030 UBW90 tool set, even 4 mm thick mild steel can be precisely bent over a length of up to 2.50 m. This makes new applications possible and reliably overcomes restrictions relating to material thickness and length. Restrictions with heavy or large format components are now a thing of the past.

TecZone Bend

Save time and increase quality during the automatic creation of your programs on the basis of 2D or 3D data. This is possible using TecZone Bend, the programming system for automatic offline programming of TruBend Center panel benders.

Software

The software portfolio from TRUMPF optimizes your entire production process – from the customer query through to delivery of the finished part. TRUMPF intelligently combines the software with machines and services to create customized digital manufacturing solutions for your Smart Factory.

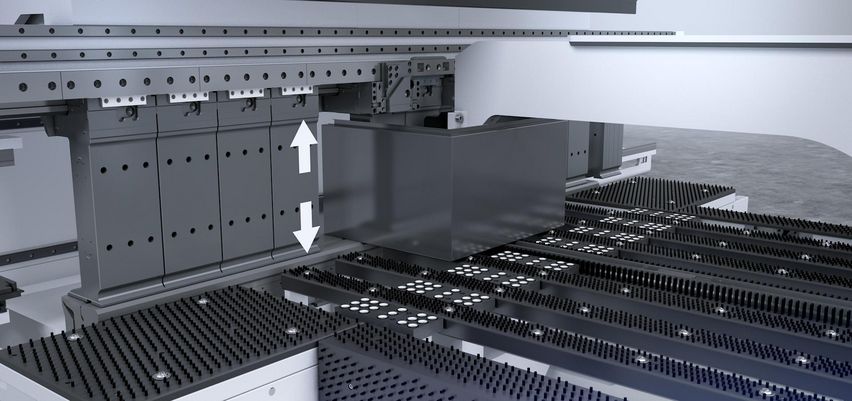

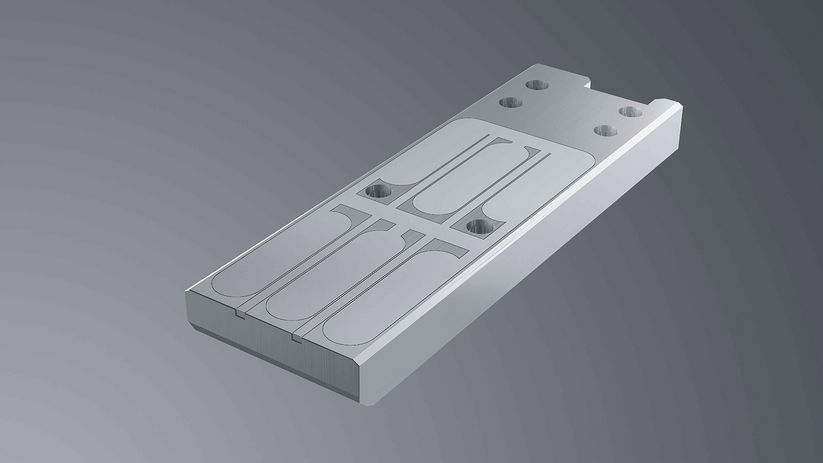

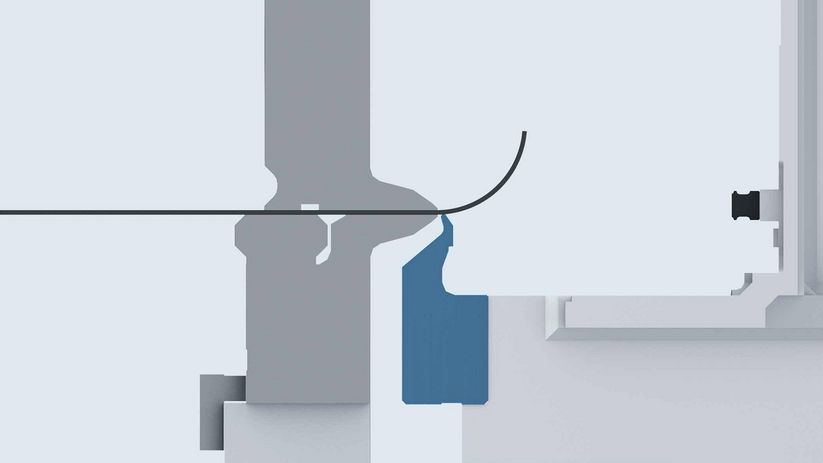

With the extra blank holder tool, you can also produce very narrow profiles or components with deformations close to the bending lines. If necessary, the machine automatically swivels the tools in from above. The existing standard blank holders do not need to be replaced or modified. This avoids restrictions with tight bending contours and frequent tool changes.

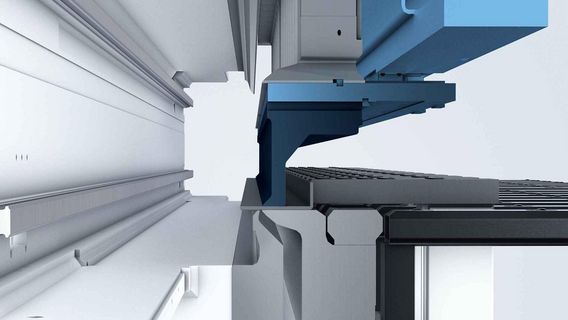

Additional bending tools can be positioned automatically to bend tabs or offset bends. If required, the tools automatically move from their lateral parking position to the correct location and process the sheet metal.

Nestings with inner edges can be produced easily with the horn blank holders. The horn tools extend and retract automatically at an angle. This means that the upper blank holder can move downwards without causing a collision between the tool and the bend. This means that even components with inner edges can be produced collision-free without any problems.

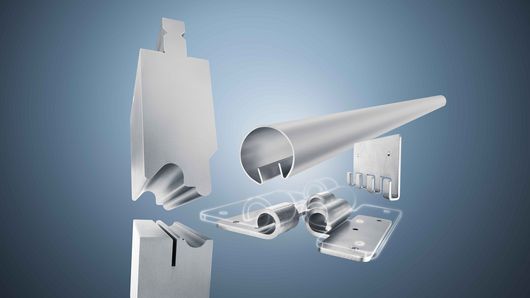

More bending freedom: Benefit from our comprehensive range of bending tools or have special tools created to your requirements. This means that even special customer requirements can be implemented flexibly and economically.

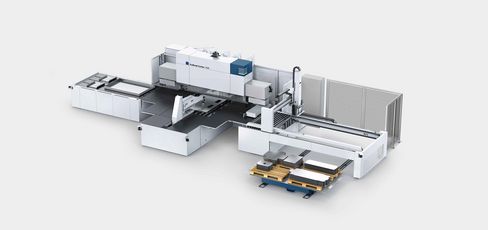

Automatic loading and unloading

Automatic loading and unloading makes the TruBend Center 7030 even more productive. The loading unit picks up the blanks on the loading unit parallel to production and automatically feeds them to the machine. The loading cart ensures the perfect flow: You simply place several blanks on pallets there, and the machine works through them. The machine uses two conveyor belts for unloading, and can either buffer the produced components individually or in sync, depending on the component size. You can also connect a robot for removing parts in an automated way.

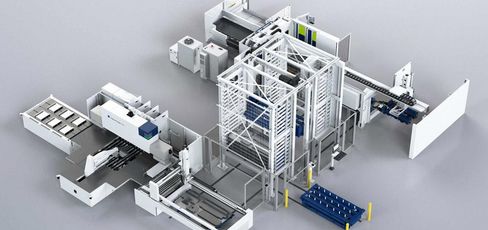

Storage connection

You can organize your material handling in line with your requirements with the TruStore 3030 store or a STOPA large-scale storage system. The storage connection is the perfect supplement to the loading and unloading unit of the TruBend Center 7030 panel bender, making you more productive.

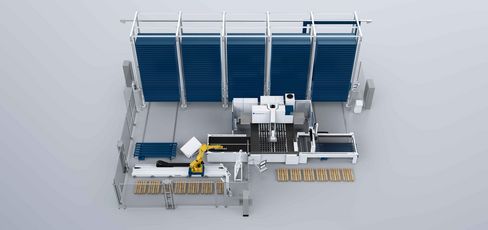

Automation solution with Starmatik

With the robot on a movable transverse rail, the TruBend Center can load and bend sheet metal up to three meters in length fully automatically. Unloading can also be completed fully automatically. During this process, the robot can even stack different orders on different pallets. The configuration is tailored to your needs. If required, you can add a storage connection, centering station, gripper and tool change, along with a regripping station and other sheet processing systems. The complete solution can be programmed offline.

This product range and information may vary depending on the country. Subject to changes to technology, equipment, price, and range of accessories. Please get in touch with your local contact person to find out whether the product is available in your country.

- 3 mm möglich bei einer max. Länge 2000 mm

- 3 mm möglich bei einer max. Länge von 1400 mm