Short-pulse lasers

Short-pulse lasers from TRUMPF are the ideal industrial-grade tool for surface treatment through to microprocessing of metals, plastics, glass and ceramics, and are suitable for a wide range of applications: Cleaning, structuring, marking, cutting and welding. With pulse durations in the nanosecond range, outputs of 20 to 2000 W and wavelengths in the infrared or UV range, materials can be processed particularly precisely and quickly at the same time - an ideal mix of quality and efficiency. The moderate heat input makes them flexible in use - from sensitive microprocessing to large-scale series production.

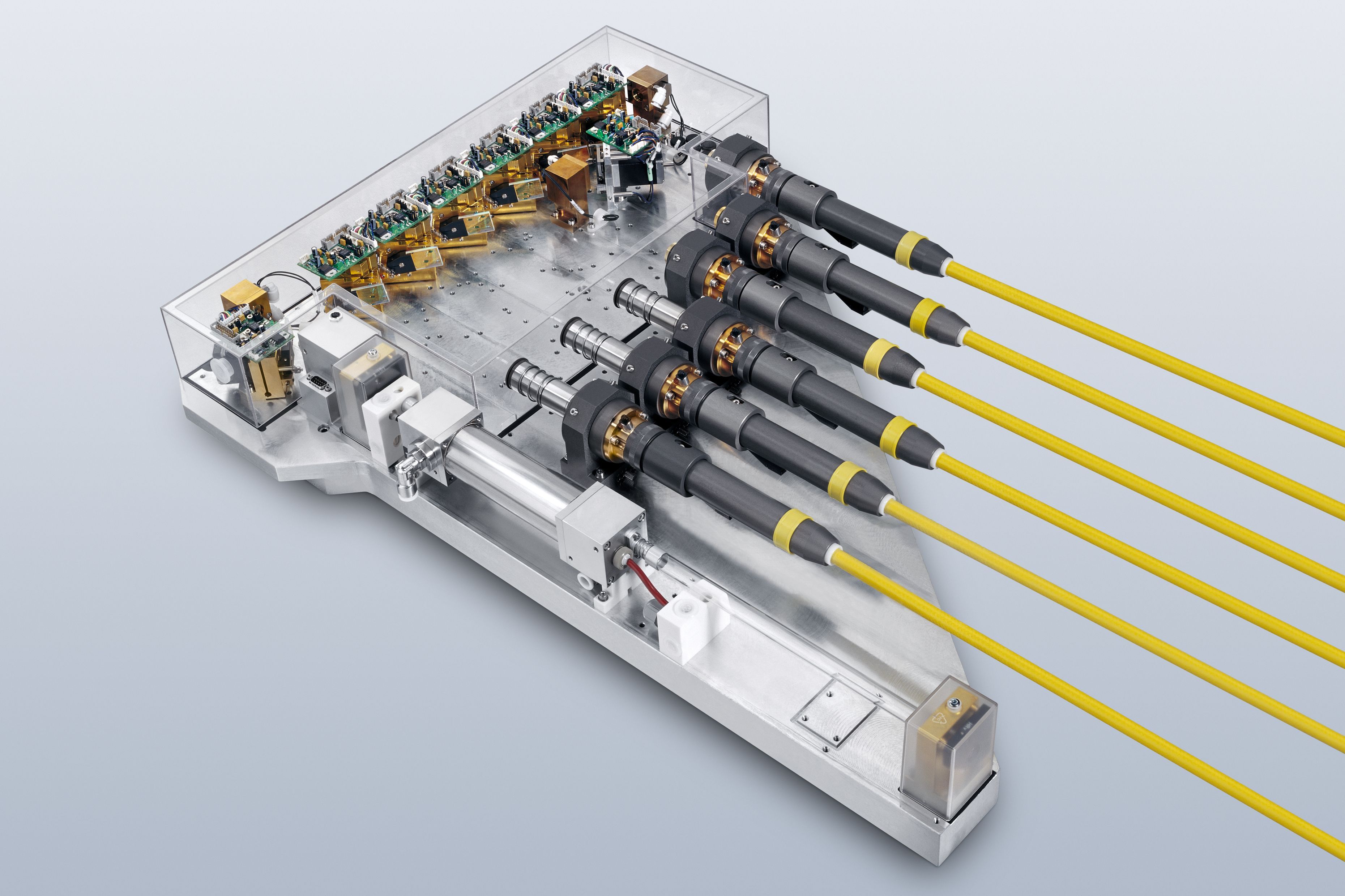

![[Translate to en_EN:] TruMark 6030 marking laser](/filestorage/TRUMPF_Processed/_processed_/6/c/csm_TruMark-6030-product-picture-2023_246ff3441e_3d7742e6e2.jpg)