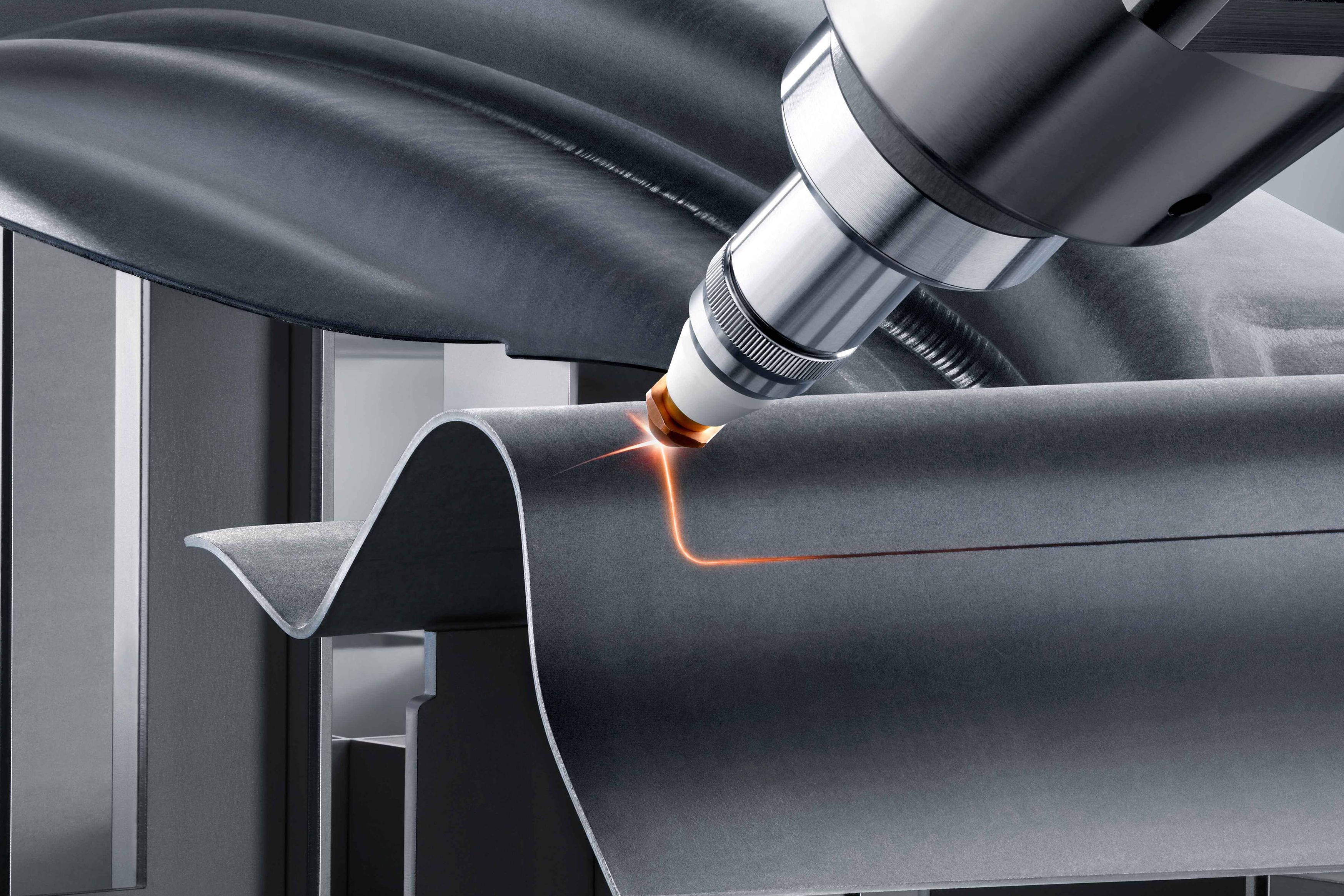

Laser for cutting

TRUMPF lasers cut metallic and non-metallic materials of various thicknesses precisely and reliably. Depending on the cutting application, fiber lasers, ultrashort pulse lasers or CO₂ lasers are used - they ensure clean cutting edges and enable the processing of (stainless) steel, aluminum, non-ferrous metals, plastics, glass, wood and ceramics. Our lasers therefore cover a wide range of applications: From delicate fine cutting to high-performance thick sheet cutting. They are used in many industries, especially in demanding production environments such as the medical technology or automotive industry.