SEAN LIN EXPLAINS THE PATH TO CARBON NEUTRALITY

Sean Lin's gaze returns to the machinery. He has set an even more ambitious energy-saving target for 2024. His focus now is on improving the energy efficiency of production processes and building technology. In future, he and his team will turn their attention to compressed air and air conditioning. The team is also creating a comprehensive energy-saving plan for a new building – including heat recovery from the ventilation system and a highly efficient cooling system.

What drives Sean Lin above all is transparency, which he believes is the key to identifying Significant Energy Users (SEUs) and uncovering opportunities to save energy. This year, his team created a platform that allows every manager to view their departmental energy consumption and every high-performance device.

TRUMPF China is the first site to be supplied entirely with renewable energy. Photovoltaics with a capacity of 1.5 MW were installed at TRUMPF China in 2021, with a further 0.4 MW due to be added soon. TRUMPF China will then produce 25% of its electricity using its own photovoltaics – and if Sean Lin and his team have their way, this will only increase in the future.

USED MACHINES EXPERT ROBIN VENEBERG

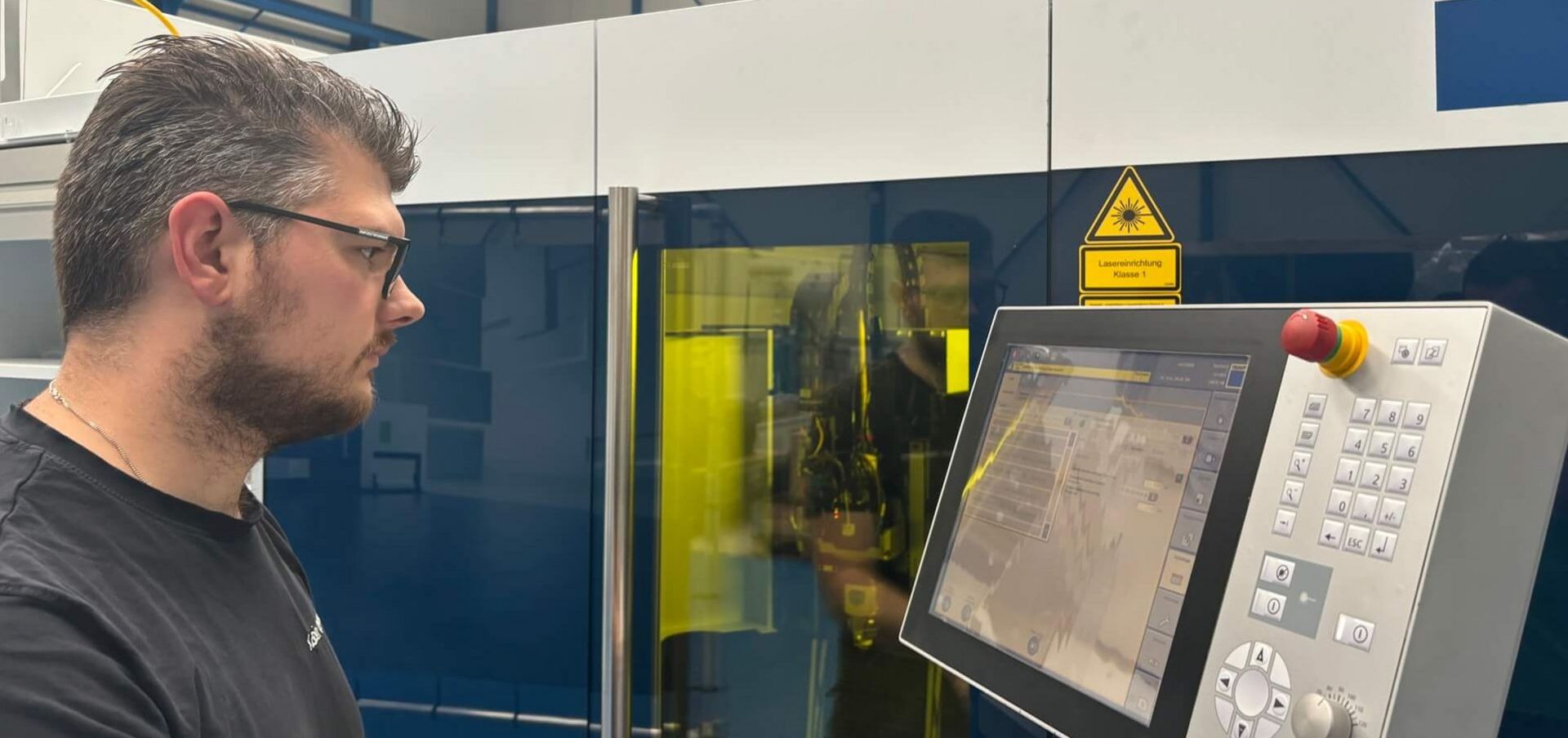

Robin Veneberg proudly points to the TruLaser 3030, which stands in the centre of the workshop. "As shiny as the day it was made," says the service engineer happily. It may look as good as new, but a customer had actually been using the 2D laser cutting machine for eight years. Two weeks ago, it found its way back to TRUMPF. At the TRUMPF Resale Centre in the Netherlands, Robin Veneberg and a total of eight other employees refurbish some 35 unused machines annually. Veneberg has been working for TRUMPF for four years, breathing new life into old TRUMPF machines. He takes care of the entire repair process, from cleaning and painting to technical inspections and replacing parts that no longer work. "Our aim is for every machine to leave the factory in 'as new' condition, both technically and visually," explains the 29-year-old. "I'm proud that my work helps advance climate protection in manufacturing," says Veneberg.

Powered by green electricity, electric cars have the potential to significantly reduce global greenhouse gas emissions. But electric car batteries rely on valuable raw materials like cobalt, manganese, lithium and nickel – and extraction of these minerals is often expensive and not always sustainable. Skyrocketing prices for battery raw materials are currently exacerbating the issue. In addition, manufacturers have to endure long and uncertain supply chains. Transporting these valuable raw materials across continents to battery factories not only takes time but also generates significant emissions. The EU also stipulates a recycling rate of up to 95% for certain battery materials. For these reasons, reusing every gram of raw materials in batteries wherever possible makes sense not only in economic and ecological terms, but is also a political necessity.

To recycle batteries on an industrial scale, Rettenmeier is developing new laser applications in conjunction with colleagues from the Laser Application Centre in Ditzingen and TRUMPF's customers. This will enable car manufacturers, battery manufacturers and recyclers to recycle used or faulty batteries from electric cars on an industrial scale for the first time. The laser systems can cut open the used batteries safely and remove the valuable raw materials from the battery foil. Rettenmeier and his colleagues can draw on TRUMPF's extensive expertise in laser welding and cutting for the production of electric vehicle batteries. TRUMPF has been working with all leading car and battery manufacturers for years.