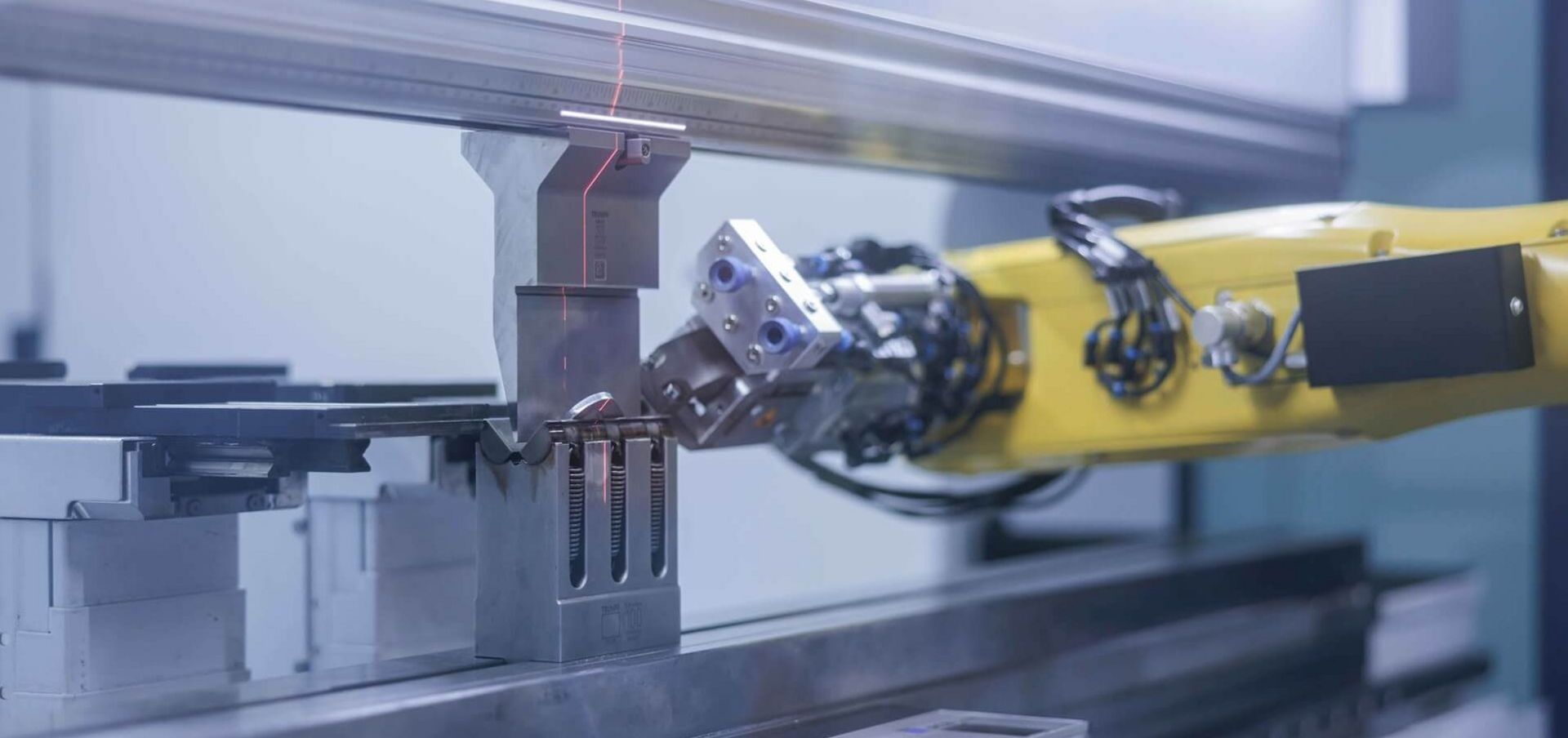

It's half past six in the morning in the Steinhuber production hall: Ferdinand Steinhuber inspects parts that were processed overnight on the TRUMPF TruBend 7050 bending machine equipped with Flex Cell bending automation. He is extremely satisfied, and delighted that his brother Gerhard has found the perfect solution for getting started with automated bending. "It's too early to give any concrete figures after such a short time," he says. "But productivity has increased significantly and our delivery times have also become shorter because we can now also run unmanned night shifts."

Why automate? Reality demands it!

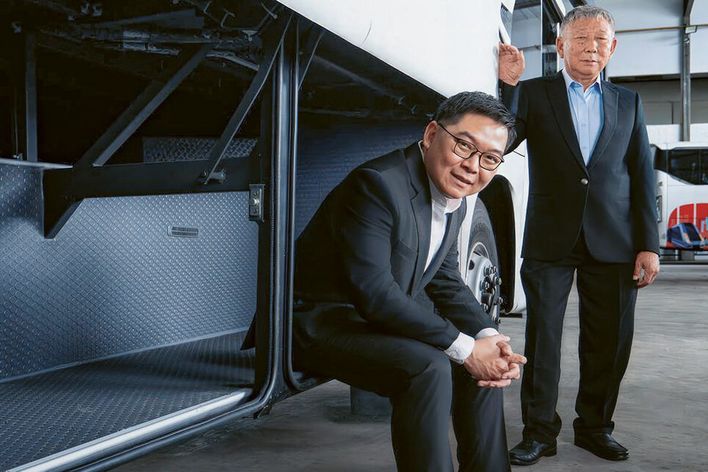

The brothers Ferdinand and Gerhard Steinhuber never put anything off: ever since founding their Austrian-based sheet metal production company S&S Steinhuber in 1997, they have stood for innovative spirit, and have invested boldly, but always carefully, in state-of-the-art technologies. "We have now positioned ourselves as a full-service provider in sheet metal manufacturing and always focus on the current requirements of our customers," explains Ferdinand Steinhuber, who is responsible for commercial operations at the company. His brother Gerhard is responsible for production and the machinery, which he has continuously expanded in recent years.

"We manufacture lot sizes from one to 100,000 pieces on our six state-of-the-art laser cutting systems and two punch laser machines from TRUMPF," he explains, continuing: "As lasers are becoming faster and faster, we have been considering automated bending for some time. This allows us to create more efficient processes and increase productivity and production quality." Ferdinand adds with a smile: "This makes our customers happy, and of course our skilled workers are enthusiastic about modern automated bending systems, which also reduces their workload."

Get in, get started and be inspired

When the entrepreneurs first heard about TRUMPF's flexible, retrofittable Flex Cell bending automation system, they hesitated until it was announced that it would also be available with the angle sensor ACB in 2024. "The issue of processing quality caused us some headaches when it came to automated bending," admits Ferdinand Steinhuber. "We didn't want to make any compromises. Almost all of our bending machines are equipped with the angle sensor ACB. We are real fans, because ACB guarantees consistently precise angles and offers high process reliability. Of course, we don't want to do without that in automated processing either."

In September 2024, the time had come: An existing TruBend 7050 bending machine was equipped with a Flex Cell, and the Steinhubers were delighted. "After just two weeks, the machine was firmly integrated into our production and has really stepped up the pace," says Gerhard Steinhuber, adding: "It quickly became clear that the Flex Cell was the ideal solution for us in terms of cost-benefit ratio."

Reason enough to follow up immediately: Ferdinand and Gerhard Steinhuber decided to order another TruBend 7050 including Flex Cell, and TRUMPF delivered the system in January 2025. "We have automated our bending processes considerably in less than six months," says a satisfied Ferdinand Steinhuber. "This gave us maximum flexibility." This was important to the brothers. "A fully automated bending cell is a big investment, especially if you are not sure whether you will be able to utilize it to full capacity," explains Gerhard Steinhuber.

Perfect cost-benefit ratio

However, this problem does not arise with Steinhuber. Over 50 different parts are now bent there automatically - and the number is constantly increasing. "TRUMPF used the online data from the machines to show us that we had already completed almost half a million bends on the two machines after such a short time - that surprised us, but also confirmed that the investment had paid off," says Ferdinand Steinhuber. The fact that the programming was challenging at the beginning did not slow down the Steinhuber team.

"We have a great team here who were enthusiastic about what they were doing and quickly got the hang of it," says Gerhard Steinhuber proudly. For simple parts with one or two bends and a simple contour, the Flex Cell is ready for use in around an hour; for more complicated parts, it takes a little longer, he explains: "The staff need to be more highly qualified, but once the system is up and running, it runs smoothly and our skilled workers can spend time completing other work."

Fully automated in 25 minutes

Although both automated systems are currently in continuous use, the Steinhubers agree that the option of switching the TruBend 7050 back to manual operation if required is a great feature. The entire system requires less than ten square meters of space and - the real highlight - it can easily be pushed aside. "So far, we have never disconnected our two Flex Cells," says Ferdinand Steinhuber. "Of course, we learned how to disconnect it during training. The effort was minimal. The automation was disconnected, moved, reconnected and recalibrated in just 25 minutes."

This flexibility, the reduced workload for their employees, the more efficient production and the consistent quality of the parts convinced the Steinhubers of the benefits of the Flex Cell. "The system is fast, and the robot always picks up parts consistently and correctly, even asymmetrical ones. Added to this is the angle sensor ACB, which ensures process reliability - it doesn't get any better than this," summarizes Ferdinand Steinhuber.

Big automation in a small space - learn more about the Flex Cell, one of many highlights at Blechexpo:

Lightning-fast offline programming with integrated collision monitoring ensures smooth processes without compromise. With a minimum footprint of less than 10 m², you can maximize both productivity and flexibility. Small parts automation offers a cost-efficient entry point into automated production.

Secure your free ticket now and meet us from October 21 to 24, 2025 at Blechexpo in Stuttgart!